我们只做高品质的产品

公司以诚信、实力和产品质量获得业界的认可,欢迎各界朋友莅临参观,指导和业务洽谈

-

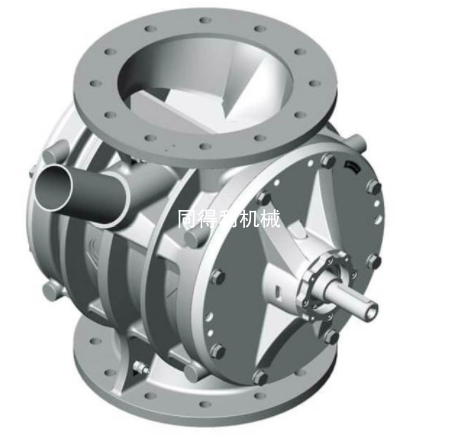

【水冷式】高温高压旋转阀>1000℃>1MPa/ 水冷式旋转阀,高温旋转阀,高温星型卸料器,高压旋转阀

产品介绍★耐高温高压旋转阀/卸料阀/星型卸料器主要用于钢厂、电厂、环保行业、航空航天、锂电、化工等。 ★适用于温度过高的物料,很好的降温。【电话/微信咨询:陈经理18068546632】 ★阀体:采用整体浇铸于不锈钢全 面通水降温。 ★端盖采用全 面通水降温,避免轴承传递高温。 ★叶轮主轴采用全 面通水降温,避免高温形变,影响同心度。 ★针对有腐蚀物料、有害气体,实现零泄漏、耐腐蚀、耐磨。压力<1MPa为常规品,高压大于2MPa或20Kg/² 可定制。【电话/微信咨询:陈经理18068546632】 ★温度小于1000℃为常规品,高温大于1300℃ 可定制。 ★常州同得利拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粉料、超微粉体等。【电话/微信咨询:陈经理18068546632】 在常规水冷式技术基础上,我司已研发出全局式通水降温,更耐高温!好的产品需要企业不断科技创新,我司拥有强大科研能力以及创新能力,研发生产各种非标定制版旋转阀卸料阀。打造国家民族品牌旋转阀,成就奋斗者的幸福人生! 《扫二维码-添加 陈经理 微信-咨询高温高压旋转阀》 High temperature and high-pressure rotary valves/discharge valves/star shaped unloaders are mainly used in steel mills, power plants, environmental protection industries, aerospace, lithium batteries, chemical industries, etc. Suitable for materials with excessively high temperatures, it effectively cools down. Valve body: It is cast as a whole in stainless steel and fully cooled by water flow. The end cover adopts comprehensive water cooling to avoid bearing transmission of high temperature. The impeller spindle adopts comprehensive water cooling to avoid high-temperature deformation and affect concentricity. To achieve zero leakage, corrosion resistance, and wear resistance for corrosive materials and harmful gases. Pressure<1MPa is a standard product, while high pressure greater than 2MPa or 20Kg/² can be customized. Temperature below 1000 ℃ is a standard product, while high temperature above 1300 ℃ can be customized. Changzhou Tongdeli has many years of experience in research and development, production, and customization of discharge valve rotary valves, adhering to the principle of quality first and customer first. Our rotary valves are capable of handling various types of particles, flakes, blocks, powders, ultrafine powders, etc. in industries such as lithium batteries, steel mills, power plants, cement, mining, environmental protection, plastics, chemical, food, and pharmaceuticals. On the basis of conventional water-cooled technology, our company has developed a global water cooling system that is more resistant to high temperatures! Good products require continuous technological innovation from enterprises. Our company has strong research and innovation capabilities, and has developed and produced various non-standard customized rotary valve discharge valves. Build a national ethnic brand rotary valve and achieve a happy life for hardworking people!查看详情 +

-

【高密封】滑杆式旋转阀-锂电/化工/食品/ 清洗型旋转阀,高端品牌旋转阀,滑杆式旋转阀,滑杆卸料阀,锂电旋转阀,化工旋转阀,食品旋转阀

产品介绍进口品牌德国科贝隆Coperio**,zeppeli**泽普琳、荷兰DMN、格律克Gericke、威埃姆WAMGROUP、芬兰BMH、美国派力特隆pelletron旋转阀 。常州同得利专注研发生产高端旋转阀,拥有多年的研发生产/定制非标旋转阀卸料阀的经验,口碑好,旋转阀性能优越,让物料更流畅,使用更精久。 国产选大品牌-国盛商标常州同得利,专 利技术,匠心质造。工匠精神是中国的瑰宝,它是我们民族文化的结晶,更是中华民族的灵魂所在。【电话/微信咨询:陈经理18068546632】 滑杆式旋转阀/星型卸料阀/关风机卸料器/旋转供料器主要结构:外壳金属;物料接触部分:内衬陶瓷、陶瓷氧化铝、尼龙、四氟、特氟龙、钛合金、铝合金、不锈钢。 尺寸:DN50~~非标定制。 清洗型滑杆式旋转阀制作精致、成功使用德、日技术制造之精华。产品拆装灵活、易于清洗。主要用于锂电、化工、制药、食品等行业高卫生标准的物料卸料及经常更换物料的场所工作。本产品对标全球一线品牌的旋转阀,性能更优,价格&交期更好! 清洗型旋转阀特点:物料粘接设备,可以快速清理,快速复位。稳定性优于其他开拆式阀门,可原地抽出转子。清洗前的拆卸:松开活动端盖上的螺旋手柄,沿柱将端盖和转子一起拉出,松开轴端的螺旋手柄,取出转子。清洗后,装入叶轮(转动叶轮使花键齿合),推入端盖(转动活动轴柄使花键齿合),拧紧螺栓手柄。【电话/微信咨询代替方案:陈经理18068546632】 滑杆式旋转阀主要用于输送锂电池正极材料、磷酸铁锂、三元材料、化工粉料/颗粒、食品、塑料等。 同得利秉承以下服务承诺: 服务目标:服务质量赢得用户满意。 严格控制对产品性能的检测,待产品被确认合格后再出厂发货。 提供的产品符合报价文件承诺和所签合同规定的技术要求。 物美价廉,具有输送系统完全密闭,可以避免输送物料的受潮、污损或混入异物等优势,常用于锂电/化工/药材/食品/塑料/钢厂/电厂/矿山/水泥/环保等行业。 全新的铸造方法用于改善外表面光洁度和铸造完整性,阀体外壳强度更高。【电话/微信咨询:陈经理18068546632】 我公司是集科研、开发、设计、制造、售后服务于一体的环保型机械重 点企业。公司地处经济发达的长江金三角,坐落在全国闻名的科技示范城-龙城常州,地理位置优越,千年古运河入境而过,沿江高速、京沪高速、沪宁高速纵横交错,交通十分便利。 公司在强化企业管理的基础上,依靠科技进步提高技术含量,先进的生产加工设备,领 先的管理理念,高素质的员工团队,有效的质量保障体系和完善的售后服务,为制造高品质的产品提供可靠的保证,极大的满足了各行业的需求,深受广大客户的信赖。 我公司始终坚持“质量第 一、用户至 上”的宗旨,服务于社会,诚信于业界,竭诚欢迎世界各地的业界好友光临指导,洽谈合作。【电话/微信咨询:陈经理18068546632】抛光处理: Domestic selection of major brands - Guosheng trademark Changzhou Tongdeli, patented technology, craftsmanship and quality. The spirit of craftsmanship is a treasure of China, a crystallization of our national culture, and the soul of the Chinese nation. Sliding rod rotary valve/star shaped discharge valve/shut-off fan unloader/rotary feeder Main structure: metal shell; Material contact parts: lined with ceramic, ceramic alumina, nylon, PTFE, PTFE, titanium alloy, aluminum alloy, stainless steel. Size: DN50~~Non standard customization. The cleaning sliding rod rotary valve is exquisitely made, and successfully uses the essence of German and Japanese technology. The product is flexible in disassembly and easy to clean. Mainly used for unloading materials with high hygiene standards in industries such as lithium batteries, chemicals, pharmaceuticals, and food, as well as working in places where materials are frequently replaced. This product is benchmarked against top global brands of rotary valves, with better performance, price, and delivery time! Characteristics of cleaning type rotary valve: Material bonding equipment, can be quickly cleaned and reset. Stability is superior to other detachable valves, and the rotor can be pulled out in place. Disassembly before cleaning: Release the screw handle on the movable end cover, pull out the end cover and rotor together along the column, release the screw handle on the shaft end, and remove the rotor. After cleaning, install the impeller (rotate the impeller to engage the spline teeth), push in the end cover (rotate the movable shaft handle to engage the spline teeth), and tighten the bolt handle. Sliding rod rotary valves are mainly used for transporting lithium battery cathode materials, lithium iron phosphate, ternary materials, chemical powders/particles, food, plastics, etc.查看详情 +

-

【第3代陶瓷旋转阀】耐高温-耐磨-耐腐蚀-锂电①选/ 锂电旋转阀,陶瓷关风机,陶瓷旋转阀,陶瓷星型卸料阀,陶瓷旋转卸料器

产品介绍星型卸料器/旋转阀/旋转卸料阀/关风机常用在气力输出系统中。对于压力输出系统或负压输出系统,星型卸料器可以均匀、连续地向输料管供料,以保证气力输出管内的气、固态比较稳定,从而使气力输送能正常工作,同时又能将卸料器的上、下部气压隔断而起到锁气作用。因此,星型卸料器是气力输送系统中常用的重要设备。 Star shaped unloaders/rotary valves/rotary discharge valves/shut-off fans are commonly used in pneumatic output systems. For pressure output systems or negative pressure output systems, the star shaped unloader can uniformly and continuously feed the conveying pipe to ensure that the gas and solid in the pneumatic output pipe are relatively stable, so that the pneumatic conveying can work normally, and at the same time, it can also block the upper and lower air pressure of the unloader and play a role in air lock. Therefore, the star shaped unloader is an important equipment commonly used in pneumatic conveying systems. 陶瓷星型旋转阀由本公司自主研制,已取得多项国家专 利。本品适用于不可接触金属物料,多用于锂电正极原料的生产制作。陶瓷旋转阀的优点是超强耐磨,而且不会对锂电材料造成污染,是新能源大开发进程中一大助力。【电话/微信咨询:陈经理18068546632】 The ceramic star shaped rotary valve is independently developed by our company and has obtained multiple national patents. This product is suitable for non-contact metal materials and is mainly used in the production and manufacturing of lithium positive electrode materials. The advantages of ceramic rotary valves are super strong wear resistance and no pollution to lithium battery materials, which is a major boost in the process of new energy development. 陶瓷星型旋转阀 主要结构:外壳金属或全陶瓷。 物料接触部分:内衬陶瓷(也可尼龙、四氟、特氟龙、聚氨酯等)。 陶瓷星型卸料阀 适用范围: 锂电行业:用于输送电池正负极材料、磷酸铁锂、三元材料等。 也可适用于化工、制药、水泥、矿山、电厂、造纸等各类有磨损的干粉尘介质输送卸料。【电话/微信咨询:陈经理18068546632】 特点:陶瓷旋转卸料阀具有密封性能好、耐磨性强、耐高温、耐腐蚀、保证物料的干净度、无卡灰或积灰现象、使用寿命长等特点。 全陶瓷/内衬陶瓷旋转阀作用: 耐高温:适应锂电生产过程中的高温环境,不易变形或损坏。 耐腐蚀:能够抵御锂电材料中的腐蚀性介质。 耐磨:硬度较高,能够承受物料的磨损。 精准控制:能够实现对卸料量的精准控制,满足生产工艺要求。 密封性好:确保物料在输送过程中不会泄露,保证生产环境的清洁和安全。 易于清洁:陶瓷表面光滑,不易粘附物料,方便清洗和维护。【电话/微信咨询:陈经理18068546632】 陶瓷旋转阀类型:滑杆式/侧快拆/耐高压/耐高温/锁风式/风送滑杆式/防卡型旋转阀,这些类型的旋转阀均可定制内衬陶瓷材质。(总有一款适合您的需求)【电话/微信咨询:陈经理18068546632】 高温陶瓷: 高铝瓷:耐高温度在1600度左右。 氧化锆陶瓷:某些类型可以承受高达2000度或以上的温度。 氧化铝陶瓷:熔点约为2050℃,能在非常高的温度下保持稳定性能。 碳化硅陶瓷:耐温能力可达2500度左右。 氮化硅陶瓷:耐高温达2800度左右。【电话/微信咨询:陈经理18068546632】 【常州同得利】技术研发于2015年,批量生产于2017年,2020年更新第3代陶瓷星型阀,目前有陶瓷星型旋转阀发明专 利。 Ceramic rotary valve types: sliding rod type/side quick release/high pressure resistance/high temperature resistance/air lock type/air supply sliding rod type/anti jam type rotary valve. These types of rotary valves can be customized with ceramic lining material. (There is always one that suits your needs). Changzhou Tongdeli's technology was developed in 2015 and mass-produced in 2017. The third generation ceramic star valve was updated in 2020. and currently holds an invention patent for ceramic star rotary valves. 部分客户需求: 1、输送物料磷酸铁,温度130℃左右;蕞大输送量 19.2m³/h,电机功率:1.5Kw,入出口尺寸:DN300.H400mm,16L/转,40转/分钟,材质304不锈钢,8叶片转子、内腔陶瓷阀芯,M12*8法兰孔连接,配备变频电机。 2、DN200内衬陶瓷旋转阀,物料:球形硅微粉;硅材料,电子粉体材料、非金属材料、新型金属材料、石墨及碳素。 3、输送物料磷酸铁,温度130℃左右;入出口尺寸DN200.H300mmm\6L\0.75KW,材质304不锈钢,8叶片转子、内腔陶瓷阀芯,M20*8法兰孔连接,配备变频电机。【电话/微信咨询:陈经理18068546632】 4、DN200星型给料阀,主体材质为SUS304.阀体及叶片表面冷喷涂陶瓷0.3mm;两边端盖板表面冷喷涂陶瓷0.3mm;进出口为HG/T20592 PN10标准DN200平面法兰;配变频减速电机,功率约0.75kw,能效等级IE4.防护等级IP55.绝缘等级F,脂润滑 轴封方式为盘根+气密封,轴承材质为SUS304;物料接触及裸露部分禁铜铁锌。 5、物料:磷酸铁锂/石墨类,物料堆积比重0.3~1.2g/㎝³,法兰连接DN200.流量要求:≥3t/h,材质SUS304.设备要求禁铜禁锌,卸料阀(关风器)高度≤300mm,工况:上端常压,下端负压,耐爆ExdllBT4. 6、物料:多晶硅粉,粉体,带细小颗粒,DN100.容积0.6L/转,工作温度60-100℃,物料粒度:20-300μm,物料处理量400-500Kg,输送压力≥0.5Mpa,回转阀填充系数0.6-0.7.回转阀转速29R/min,端盖材质304.转子材质304(内衬陶瓷),外壳材质304(内衬陶瓷),端盖形式:外置轴承式端盖气密封,主轴密闭做成硬密封,电机功率1.5kw-380-50hz,齿轮减速机国茂GKAF-59-48.89.【电话/微信咨询:陈经理18068546632】 7、物料:锂电粉料,粉料防金属,用内衬陶瓷或聚氨酯,陶瓷的和钛合金材质的对比下;单水氢氧化锂、碳酸锂、元明粉,其他锂盐产品。 8、化工粉状物料,防腐材质、下料速度不能太多。DN50陶瓷卸料阀。 9、稀土精深加工粉末:陶瓷星型卸料阀,卸料介质:粉末;D50<1um。公称通径DN150.电机功率0.75kw,转速33 r/min,阀座/阀瓣材质:陶瓷,输送量>30L/h。密封:具备良好的轴密封,不允许粉尘进入轴承,造成损坏,也污染物料。驱动方式:马达直连驱动,两端面法兰距离:<310mm。【电话/微信咨询:陈经理18068546632】 10、物料:锂电正极材料,物料温度一百六七十度,常压,DN150陶瓷旋转阀,有些料流动性不好,加了振动,需要能耐振动。 11、多晶硅,用于合成炉加硅粉使用,DN100.端盖转子304.外壳304加陶瓷内衬,外置轴承式端盖,容积1.6L/转,工作温度60-100℃,物料粒度:20-300μm,输送压力0.5Mpa。 12、物料:锂电原料,陶瓷星型卸料阀有耐600度的吗,长期过600度粉体。 13、物料:活性碳粉料,需要直径在DN100的四氟或者陶瓷材料的旋转阀,重力输送。 14、旋转下料器高度400.DN200法兰盘,PN16带气密封的,全陶瓷旋转阀,锂电行业用。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询陶瓷旋转阀》查看详情 +

-

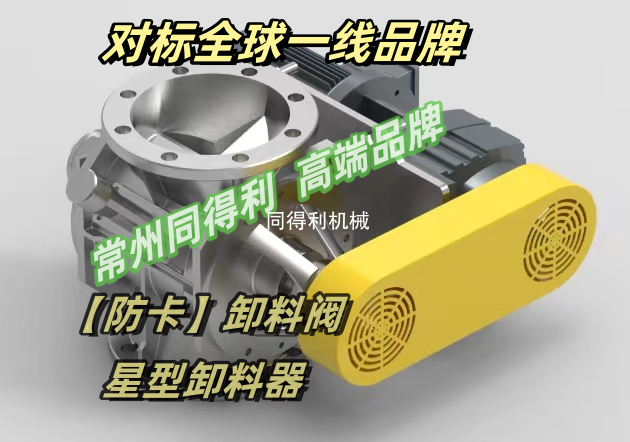

【替代进口-高密封-防卡防堵】防卡式旋转阀/ 防卡防堵旋转阀,防卡卸料阀,高端旋转阀,防卡旋转给料阀,防卡旋转卸料阀

产品介绍旋转阀(又称星型卸料阀、旋转卸料器、卸料器、星形下料器、关风机、电动锁气器、锁气阀)广泛地应用于高中低压气力输送系统中,它有定量供料与锁气的功能。它利用压缩空气或罗茨鼓风机作为气源将物料从一个点输送到另一个点的技术,具有可以将由数点集中的物料送往一处或有一处送往分散的数点,并实现输送等特点,具有粉体输送等作用,常用于锂电、化工、医药、塑料、食品、钢厂、电厂、水泥、环保、矿山、石油、冶金等行业。旋转供料器主要由主阀(壳体,端盖,叶轮,密封结构等),电机减速机,防护装置(链轮,链轮罩等),排气口等组成。 防卡旋转阀-对标全球一线品牌: 进口品牌价格贵,交期长怎么办?找国产替代,选大品牌-国盛商标-常州同得利-江苏同得利,专 利技术,匠心质造。进口品牌德国科贝隆Coperio**,zeppeli**泽普琳、荷兰DMN、格律克Gericke、威埃姆WAMGROUP、芬兰BMH、美国派力特隆pelletron旋转阀 。 防卡式旋转阀类型:防卡防堵型;气密封防卡旋转阀;鹰嘴式防卡型;偏置式防卡型。根据客户需求及实际应用工况推荐适合产品的旋转阀。【电话/微信咨询:陈经理18068546632】 防卡型旋转阀主要用于颗粒料和重力下料和气力输送卸料,配备特殊防卡结构的导流槽。进料口采用防卡进料口设计,能将物料均匀投入叶轮每个角落。根据不同介质调整间隙设计,采用V形叶片及其他特殊转子形式,物料运行更流畅。进料口设有鹰嘴防卡口设计,适用于颗粒物料输送。通过减少叶轮与阀体的接触面,物料被拨开分离有更多角度落入叶腔,减少阻力,卡滞问题。 法兰形式:圆形、方形、偏置式。 1.壳体及主要零部件采用精密铸造,外形美观。 2.设置排气口(正压输送时选用)将叶轮旋转带出的高压气体通过排气口送至排气装置,提高填充效率。【电话/微信咨询:陈经理18068546632】 3.防切料入口设计,即便上游充满物料也可安全启动。 4.高强度的阀体及轴,可承受高压且运转平稳。 5.特殊防卡料设计,避免运转中粒子剪断现象。 6.双嵌入式轴承,具有良好的强度及精度。 7.先进的轴部密封结构,采用气体吹扫装置防止粉尘进入轴承。 8.轴承外置式安装、经久耐用、性能优异。 9.提供链驱动、直联驱动多种安装方式。 10.根据需求配置减速机电机。 11.材质主要有:不锈钢304-316系列、铝合金、钛合金、哈氏合金、陶瓷系列、碳化钨等。 12.可针对不同工况非标定向设计。【电话/微信咨询:陈经理18068546632】 防卡式旋转阀可配备气密封装置: 气密封旋转卸料阀的用途广泛,特别适用于需要连续、定量卸料的场合。它能够在负压或压力输出系统中均匀且连续地将物料供给到输送管中,稳定气体固体混合物的输送,并起到遮断排出阀上下部气压的锁定功能。通过自重使上料盒的材料落下,填充叶片间的间隙,并随着叶片的旋转排出到下部,从而实现定量且连续的物料排出。 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。 使命:助力粉.粒料输送企业提升竞争力,成就中国梦! 愿景:打造国家民族品牌旋转阀,成就奋斗者的幸福人生!【电话/微信咨询:陈经理18068546632】【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询防卡式旋转阀》 部分客户需求: 1、物料:废料纤维和塑料粉尘,替代科倍隆,越南客户用,处理量:2000Kg/h堆密度:1.5Ton/m3.链轮式旋转阀,粉体粒度:平均500μm 蕞大5mm,直径0.3mm,壳体材质.不锈钢,减速机:SEW 非变频非防爆,带防卡料斗。 2、物料:不到1mm化工产品有腐蚀性,料仓下料易结块堵塞,严重影响称重计量包装,DN300接口,316L材质。【电话/微信咨询:陈经理18068546632】 3、物料:石灰活化后选粉机选后留下的渣,大部分是0-3mm,偶尔有30mm的颗粒,需要防卡型,DN250.不锈钢304材质。 4、物料:氧化铝粉和破碎电解质,控制固体颗粒物料通过料管的量要防卡型,常压输送,重力下料,DN200. 5、物料:塑料颗粒,正压输送,现在用的防卡效果不好,需要更换,不锈钢防卡型。 6、物料:颗粒状沥青,温度大约 80-90℃,卸料量:>4m3/h,转速:24r/min,材质:物料接触部分 316不锈钢,国标法兰 DN300-PN1.0 RF,双层链条传动真空型,叶片与叶片之间弧形(防粘),阀体进料口处设计导料嘴(防卡),轴封:聚四氟乙烯盘根密封,防爆电机:ExdbIIBT4 Gb IP55 2.2KW-4P。【电话/微信咨询:陈经理18068546632】 7、物料:蛋粉颗粒,除尘器下面,用传统的关风器会卡住,需要防卡型,密封性能要好,锁风,食品级不锈钢,DN200. 8、物料:白糖,DN150侧开式鹰嘴防卡,直装式减速机安装,内部抛光处理,侧开式,快装螺丝固定整体不锈钢304 卸料量:400kg/h 电机电压:DC24V 正压输送,直连式安装方向皖南:电机 YE4-1.1kw。 9、输送竖炉生产出来的熟球物料,温度在300度左右,要求要有耐磨性和防止漏风,防卡防堵,DN400. 10、物料:铝粉,不锈钢304防卡旋转阀,粉尘防爆型,DN150.每转2升,每分钟15转。【电话/微信咨询:陈经理18068546632】 11、物料:环氧树脂颗粒或片状,粒状(φ6-7mm*2-4mmm):片状(厚度4-6mm;30-40mm 见方)堆积密度(T/m3)0.7-0.8.Y型防卡设计,DN150.304材质,电机皖南防爆2级能效,安装在计量料仓下面。 12、物料:100mm焦炭,常温,常压,防卡型,20吨/小时。 13、20T-40T/H,采用加料器与轴承箱分体式设计,旋转阀进出口设W形防卡料结构,旋转阀设排气接管和防静电接地柱(板),链轮、链条传动16A-1.非接触式密封,法兰DN350/垫片φ350/螺栓M20*120. 14、物料:磷酸铁锂锂电使用,DN300.防卡防堵易清理型自动星型卸料阀:阀体容积:12L左右;材质:壳体材质 304 ,与物料接触部分喷涂非金属材质(氧化铝陶瓷,厚度≥0.3mm),阀芯采用尼龙材质制作;喂料产能 1~2t/h ;法兰采用国标 GB/T9112-2000. PN10. RF;驱动 选用四级电机满足 IE4 能效标准。【电话/微信咨询:陈经理18068546632】 15、物料:0-3mm萤石粉矿山,正压输送,压力0.04MPa,卸料量200公斤/h,变频,碳钢,防卡防堵。 Rotary valves (also known as star shaped discharge valves, rotary unloaders, unloaders, star shaped unloaders, shut-off fans, electric air locks, and air lock valves) are widely used in high, medium, and low pressure pneumatic conveying systems. They have the functions of quantitative feeding and air lock. It uses compressed air or Roots blower as the gas source to transport materials from one point to another. It has the characteristics of being able to transport materials concentrated in one point to one or dispersed points, and achieve transportation. It has functions such as powder transportation and is commonly used in industries such as lithium batteries, chemicals, pharmaceuticals, plastics, food, steel mills, power plants, cement, environmental protection, mining, petroleum, metallurgy, etc. The rotary feeder is mainly composed of a main valve (housing, end cover, impeller, sealing structure, etc.), a motor reducer, protective devices (sprocket, sprocket cover, etc.), exhaust port, etc. Anti jamming rotary valve - benchmarking against top global brands: What should we do if imported brands are expensive and have long delivery times? Find domestic alternatives, choose big brands - Guosheng trademark - Changzhou Tongdeli - Jiangsu Tongdeli, patented technology, craftsmanship and quality. Type of anti card rotary valve: anti card and anti blocking type; Airtight anti jamming rotary valve; Eagle beak anti jamming type; Offset anti jamming type. Recommend suitable rotary valves for the product based on customer needs and actual application conditions. Anti jamming rotary valves are mainly used for granular materials, gravity feeding, and pneumatic conveying unloading, equipped with special anti jamming structures and guide grooves. The feed inlet adopts an anti jamming design, which can evenly feed materials into every corner of the impeller. Adjust the gap design according to different media, adopt V-shaped blades and other special rotor forms, and ensure smoother material operation. The feed inlet is equipped with an eagle beak anti lock design, suitable for conveying granular materials. By reducing the contact surface between the impeller and the valve body, the material is separated and more angles fall into the blade cavity, reducing resistance and jamming problems. Flange forms: circular, square, offset.查看详情 +

-

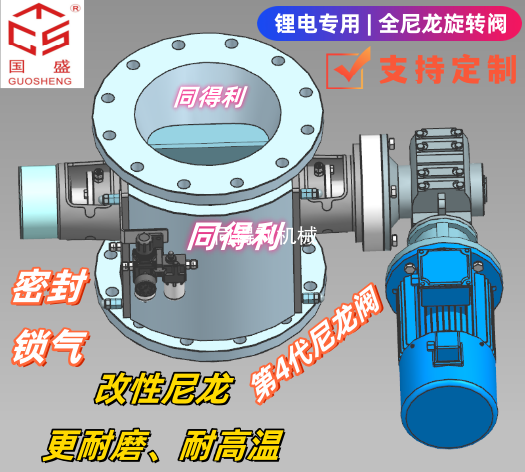

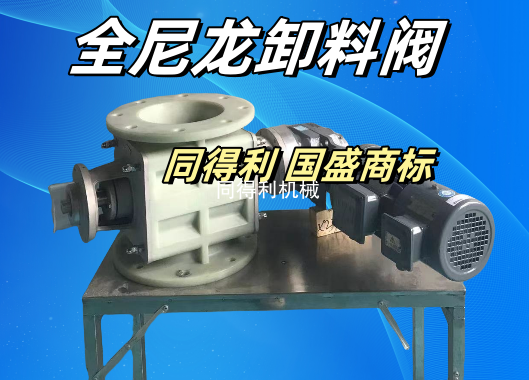

【锂电-推荐】改性全尼龙旋转阀-防金属耐磨耐高温/ 锂电旋转阀,尼龙星型卸料阀,尼龙旋转给料阀,全尼龙旋转阀

产品介绍全尼龙旋转阀用于不可接触金属物料的卸料。箱体、叶轮以及端盖,都采用整块尼龙铣削加工,结构牢靠,运行无噪音,相较于陶瓷星型旋转阀,可以节省成本,是锂电行业新宠。 改性尼龙星型旋转阀特点:改性尼龙比普通尼龙更耐磨、耐高温。适用于锂电正极材料输送,高镍三元材料,磷酸铁锂等。可以满足工况耐磨,耐高温尤为突出。【电话/微信咨询:陈经理18068546632】 这款全尼龙星型旋转阀,相比于传统的304内衬工艺,喷涂碳化钨四氟和陶瓷粉等工艺,全尼龙卸料阀更为优越,它不仅能保证阀的强度和耐磨性,还具备锁风密闭的功能,让物料更流畅,使用更精久。 全尼龙卸料阀采用加厚叶轮设计,与壳体配合间隙小,结构精密,使用过程中不易漏风不易漏料,防堵耐用。【电话/微信咨询:陈经理18068546632】 密封优越,用感无忧:结构稳定,高精度密封性能。可用于粉料、小颗粒物料,在正负极压差吸送过程中将物料分离排出。 尼龙星型阀技术研发于2016年,批量生产于2018年,2020年更新第4代尼龙星型旋转阀,目前有尼龙星型旋转阀专 利。【电话/微信咨询:陈经理18068546632】 全尼龙卸料阀特点: 1、良好的耐磨性能: 尼龙材料具有优异的耐磨性,尼龙旋转卸料阀的使用可以有效减少阀门的磨损程度,提高阀门的使用寿命。 2、良好的耐高温性能: 所采用的材料具有良好的高温稳定性,可在高温条件下安全使用。它是一种用于输送介质的可靠材料。【电话/微信咨询:陈经理18068546632】 3、良好的气密封性能: 壳体与旋转叶轮之间的间隙,实现了锁气功能,避免了气体泄露的问题,全尼龙卸料阀的两端采用了气密封装置,确保了阀的密封性。 4、良好的耐腐蚀性能: 尼龙旋转卸料阀的材料能够很好地抵抗酸、碱等化学介质的侵蚀,具有优异的耐腐蚀性能,适用于各种介质的输送。【电话/微信咨询:陈经理18068546632】 常州同得利机械厂/江苏同得利拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。 【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询尼龙旋转阀产品》 部分客户需求: 1、锂电行业,尼龙旋转阀,采用变频器控制下料速度;耐磨尼龙转子,阀体材质SUS304内衬尼龙,间隙设计需防止受热卡顿。轴套需非金属耐磨,且轴套长度需延伸到尼龙转子的端面;阀体侧壁偏下设吹气孔*2.并外延出 304 不锈钢吹气管,吹气管上配置 DN15 不锈钢手动球阀;1.5.电机采用变频电机,减速机采用齿轮;1.6.旋转阀总高度约405mm,有效容积≥6L,额定转速25转/min(变频可调)。 2、物料:磷酸铁锂,旋转阀DN200.转子尼龙、阀体喷涂F46.高290 PN10 转速25.能力4.5t/h,堆密度0.7. 3、全尼龙、锂电池、DN200-高300.电机0.75KW。 4、物料:锂电行业,壳体:304不锈钢,内表面及法兰口内衬≥3mm厚尼龙,DN200 PN10 RF,叶轮:304不锈钢,外表面衬≥3mm厚尼龙,一体成型。旋转轴:304不锈钢材质。盘根密封:不漏料跑料,四氟材质,结构5层。电机:江特、卧龙、皖南、南洋,变频控制。减速机:摆线针式或齿轮式,设置注油口,品牌:国贸。 5、物料:碳酸锂,DN150-2L,之前用的不锈钢,现在想换尼龙旋转阀,三元前驱体、三元正极材料、氢氧化镍等电池正极材料。 6、物料:三元前驱体,配套盘式干燥机下料口用的,全尼龙DN200旋转阀,33r/min,6L。 7、物料:磷酸铁锂,全尼龙旋转阀,需要气密封,以往项目漏粉比较多,所以需要高精度密封型。 8、物料为磷酸铁锂锂电使用,DN300.产能3.6t/h,易清理型自动星型喂料阀:阀体容积:12L左右;材质:壳体材质 304 ,与物料接触部分喷涂非金属材质,阀芯采用尼龙材质制作;喂料产能 1~3.6t/h ;法兰采用国标 GB/T9112-2000. PN10. RF;驱动 选用四级电机满足 IE4 能效标准。检修门配有欧姆龙品牌的限位开关;驱动选用SEW、FLENDER、住友等外资品牌,变频控制;选用四级电机满足 IE4能效标准,轴承品牌SKF斯凯孚、FAG或NSK;油封品牌UKS、优泰科(UTEC)、或Freudenberg(科德宝),进口和壳体配置防堵料装置,保证旋转阀下料顺畅。 9、介质:HDPE粉尘+丝带,尼龙旋转阀DN250材质304不锈钢,设计环境温度:-40.2℃~36.6℃;海拔:186.8-300m; 设计湿度:70%。 10、物料:石英二氧化硅粉料,负压-磨损比较厉害,需要改性尼龙。 11、物料名称:抗氧剂,DN150.物料堆积密度:400~600kg/m3.工况:气力输送,工作温度:50°C,与物料接触材质尼龙,输送能力0.3~0.35T/h,主体结构:开式叶轮,轴气封,轴承外置,背包式,容积效率:45%,叶轮转速18rp。 12、物料:石英粉,三四百目-纯度要求高,需要防金属接触,目前在用的碳钢阀体,所以需要更换。 13、介质是石英砂,设计压力4.0MPa,输送量1立方/分钟,所以温度大概-25摄氏度,工作压力约3.5MPa。 14、物料:很纯99.9999%的石英砂,提炼用-70目~200目,经过分料器,不能有污染-不能有金属元素。 15、碳酸性的物料,负压,0.5左右,内衬尼龙,DN250尼龙旋转阀(含电磁锤、电控柜变频器及变频电机,产能400-500KG/H)。 All nylon rotary valve is used for unloading non-contact metal materials. The casing, impeller, and end cap are all machined with a single piece of nylon, which has a reliable structure and operates without noise. Compared with ceramic star shaped rotary valves, it can save costs and is a new favorite in the lithium battery industry. Characteristics of modified nylon star shaped rotary valve: Modified nylon is more wear-resistant and heat-resistant than ordinary nylon. Suitable for transporting lithium-ion cathode materials, high nickel ternary materials, lithium iron phosphate, etc. It can meet the requirements of wear resistance and high temperature resistance under working conditions. This all nylon star shaped rotary valve is superior to traditional 304 lining processes, such as spraying tungsten carbide PTFE and ceramic powder. The all nylon discharge valve not only ensures the strength and wear resistance of the valve, but also has the function of air locking and sealing, making the material smoother and more durable. The all nylon discharge valve adopts a thickened impeller design, with small clearance with the shell, precise structure, and is not easy to leak air or material during use, making it durable and anti blocking. Excellent sealing, worry free use: stable structure, good sealing performance. Can be used for powder and small particle materials to separate and discharge materials during the positive and negative pressure difference suction process. The nylon star shaped valve technology was developed in 2016 and mass-produced in 2018. The fourth generation nylon star shaped rotary valve was updated in 2020. and there is currently a patent for nylon star shaped rotary valve. Characteristics of all nylon discharge valve: 1. Good wear resistance: Nylon material has excellent wear resistance, and the use of nylon rotary discharge valves can effectively reduce the degree of valve wear and improve the service life of valves. 2. Good high temperature resistance: The materials used have good high-temperature stability and can be safely used under high temperature conditions. It is a reliable material used for conveying media. 3. Good gas sealing performance: The gap between the shell and the rotating impeller achieves gas locking function, avoiding the problem of gas leakage. The two ends of the all nylon discharge valve are equipped with gas sealing devices to ensure the sealing performance of the valve. 4. Good corrosion resistance: The material of nylon rotary discharge valve can resist the erosion of chemical media such as acid and alkali well, and has excellent corrosion resistance, suitable for the transportation of various media.查看详情 +

-

【破碎<10mm】旋转破碎阀-破碎卸料阀/ 破碎卸料阀,旋转破碎阀,电动破碎打散卸料阀,破碎阀,打散卸料器,块料破碎阀

产品介绍The main function of the rotary crushing valve is to crush the block materials in the material flow of the unloader. These block materials are formed by moisture in the warehouse or bin. When large blocks of material appear in the material, they can be immediately crushed to prevent them from blocking the channel of the unloading valve and improve smooth unloading. The rotor of the crushing valve is equipped with radially arranged crushing claws, which move the block materials through the grid and crush them. The operational safety of the block material crushing valve unloader is ensured by the motor speed detection device integrated in the electric control box. When some block materials in the material cannot be crushed and get stuck in the rotor, the speed detection device will alarm and automatically reverse, pushing away the block materials that cannot be crushed before proceeding with forward rotation. When both forward and reverse rotation are stuck, the crushing valve will automatically stop and wait for the fault to be resolved before running again. The speed detection device is an optional device, and this requirement needs to be explained when ordering the equipment. 旋转破碎阀主要功能是破碎卸料器物料流中的块料,这些块料是物料在库内或仓中因受潮而形成,当物料中出现较大块状物时,可立即将其破碎,以防止这些大块物料堵塞卸料阀门的通道,提高通畅卸料,破碎阀的转子上安装有放射状布置的破碎爪,拨动块料物料通过栅格并将其破碎。 块料破碎阀卸料器的运转安全性是通过在电控箱中集成的电机转速检测装置来保证,当物料中的某些块料物料无法破碎而卡住转子时,转速检测装置将报警并自动反转,将无法破碎块料物料推开后再进行正转。当正转或反转都被卡住时,破碎阀则自动停机,等待排除故障后再运行。转速检测装置为选配装置,有此要求时需要在设备订货时说明。【电话/微信咨询:陈经理18068546632】 常见破碎物料:沫煤、锂矿、结块颗粒、磷酸铁粉、电石渣烧生石灰、碳酸钙、锂电池正极材料碳纳米管材料、硬脂酸盐产品、净化灰块状物料、炭黑结块。 旋转破碎阀设计特点: 蕞大型号的通过量可达1200m3/h,或非标定做。 适用于各种气化斜槽和储库卸料出口。 为高达350度的物料温度而设计,更高温度可配水冷式定做。 低能耗,维护简单。 破碎爪和栅格板使用高耐磨材料。 集成转速检测装置(选配项)。 破碎后块料常规直径<10mm,更精细可定做。 密封锁气,可配气密封装置,高精度密封锁气。破碎阀非标尺寸可定制。 部分客户需求: 1、破碎阀DN500. PN6.介质:锂辉石酸化熟料,破碎前≤30mm,破碎到≤10mm;含水率≤6%,物料堆密度890g/m³;介质流量37t/h;工作温度300℃。 2、物料:氧化铝粉末可能结块,需要打散一下,从烘干设备出来可能会成团-破碎阀。导热粉体材料(球形氧化铝、类球形氧化铝、氮化铝、氮化硼)、电磁屏蔽粉体材料(镍包石墨),以及锂电极片涂覆及隔膜涂层材料等。 3、化工物料:三氯化锂,需要破碎,高密封不能进空气,耐腐蚀,破碎至小于30mm,以前用过德国进口科倍隆的。高纯盐酸(HCl)次氯酸钠(NaClO)合成盐酸(HCl)食品级盐酸,液氯(Cl₂)高品质氢氧化钾。 4、物料:锂电池正极材料碳纳米管,料很轻粉末,现在卸料有问题,粉末飞起来不好卸料,想把料凝固成颗粒类的然后破碎卸料。 5、物料:硬脂酸盐产品,物料有些像爆米花的形状,轻抛体积大,想破碎增大物料的堆密度,物料大小一般10-20cm,要求下料速度快,破碎越小越好,下料管道DN300.物料温度高的时候会有一点粘。 6、旋转破碎阀:DN200.PN=1.0MPa,容积:6L处理物料:净化灰(块状物料占比约5%),配防爆电机:功率:1.5KW,防爆等级ExdIICT4减速机:SAF硬齿面减速机,转速:180r/min,处理里:0.4m³/min,破碎后粒度:2-5片状,壳体材质:WCB,厚度:14mm,端盖:WCB,厚度:16mm,转子叶片:材质不锈钢,厚度8mm,叶片间隙:2-5mm,转轴材质:不锈钢,带配对法兰及紧固件。 7、物料:沫煤,要求:破碎+密封。 8、西草甲型结块,吨包物料打散进仓电动破碎阀。 9、物料:粉体材料,小结块颗粒可粉料,需要卸料破碎器。 10、物料:石灰粉,300*300.碳钢材质。【电话/微信咨询:陈经理18068546632】 11、DN300破碎阀,转数328r/min 破碎≤10mm,减速机泰隆RF47-3KW,电机不防爆品牌皖南,与物料接触部分材质304.含铜量≤0.5%,输送介质无水磷酸铁粉体材料,物料温度200℃,PH值1.8-2.5;破碎动刀淬火处理,齿厚8mm间隙10mm,破碎阀内部要求无毛刺锐边,清洁干净无残存金属和其他粉末,进出料口封闭。 12、破碎阀,破碎物料Ca0、结块料、部分浇注料,物料温度200℃,进料粒度:>50mm 的料预计10%,个别结块料可达 80mm,出料粒度<8mm,处理量45t/h,Ca0 堆积密度0.7t/m³。 13、高温电动破碎阀,块状物料水泥半成品,规格500*800.温度600℃,密封功能要好。 14、化工物料:不到15mm化工产品有腐蚀性,料仓下料易结块堵塞,严重影响称重计量包装,需要加装一台破碎卸料阀,DN300接口,316L材质。 15、物料:炭黑,结块4-5cm,旋转破碎阀不锈钢,尺寸DN300.【电话/微信咨询:陈经理18068546632】 16、物料石块,破碎卸料器1:每小时2吨左右 温度:150℃。2:大料尺寸100mm,需要处理到10mm以下。3:大颗粒量约为每小时1吨。4:现场高度500mm上下一样的法兰接口,阀体材质:316L*10mm,动静齿材质:316L*6mm,法兰材质:316L*12mm,主轴材质:316L*55mm,间隙面积:约为总面积的10%。电机11KW减速比 i=19.25减速机:硬齿面K87系列(变频防爆)。 17、旋转破碎阀,物料:盐,硝酸钠在干燥过程中,有结块,影响下游螺旋输送机。 18、物料:抗氧剂块料,有点结块,挺硬的。需要破碎阀,DN500. 19、破碎阀DN500. PN6.介质:锂辉石酸化熟料,破碎前≤30mm;含水率≤6%,物料堆密度890g/m³;介质流量35t/h;工作温度300℃。 20、炉子出来的可能存在块状盐,500-600度,需要打散,同时卸料阀要降温措施保护电机,破碎尺寸5CM以内。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理微信 咨询破碎打散卸料阀》 Common crushed materials: foam coal, lithium ore, agglomerated particles, iron phosphate powder, calcined quicklime from carbide slag, calcium carbonate, positive electrode material for lithium batteries, carbon nanotube material, stearate products, purified ash block materials, carbon black agglomerates. Partial customer requirements: Crushing valve DN500. PN6. Medium: spodumene acid clinker, ≤ 30mm before crushing, ≤ 10mm after crushing; Moisture content ≤ 6%, material bulk density 890g/m ³; Medium flow rate 37t/h; The working temperature is 300 ℃. Material: Aluminum oxide powder may clump and need to be broken up, and it may form clumps when coming out of the drying equipment - crushing valve. Thermal conductive powder materials (spherical alumina, quasi spherical alumina, aluminum nitride, boron nitride), electromagnetic shielding powder materials (nickel coated graphite), as well as lithium electrode sheet coating and diaphragm coating materials. Chemical material: Lithium trichloride, needs to be crushed, highly sealed and cannot enter air, corrosion-resistant, crushed to less than 30mm, previously used from Germany imported Kobelon. High purity hydrochloric acid (HCl) and sodium hypochlorite (NaClO) are used to synthesize food grade hydrochloric acid (HCl) and high-quality potassium hydroxide for liquid chlorine (Cl ₂). Material: Carbon nanotubes, the positive electrode material of lithium batteries, are a very light powder. There is a problem with unloading now, as the powder flies and is difficult to unload. I want to solidify the material into particles and then crush them for unloading. Material: stearic acid salt product. The material has a shape similar to popcorn and has a large volume when lightly thrown. If you want to increase the bulk density of the material by crushing it, the material size is generally 10-20cm. The material needs to be cut quickly and the smaller the crushing, the better. The cutting pipeline is DN300. and the material will be a little sticky when the temperature is high.查看详情 +

-

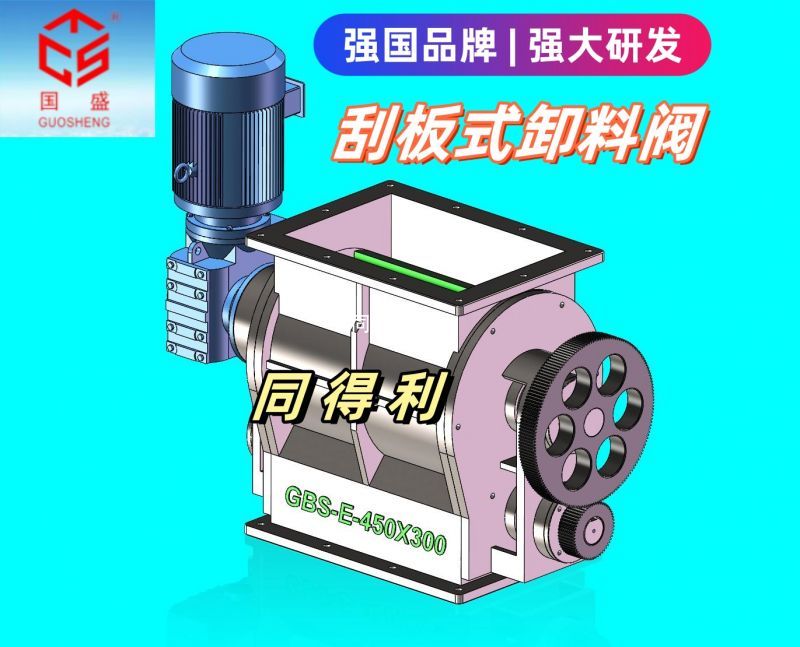

【粘性物料】刮板式旋转阀-高端品牌/ 吸湿粘性料卸料阀,刮板卸料器,刮板式旋转阀,自清理旋转阀,自清洁卸料器,钢厂旋转阀

产品介绍对于由于潮湿高水分黏附的粉粒料和由于静电易附着流动性差的粉粒料,非常容易架桥或粘附填充在旋转阀的叶片间空腔中不脱落排卸下来,将叶子空腔“糊”住,给气力输送和旋转供料器操作带来很大困难。常州同得利提供的刮板式旋转阀/卸料阀,其特点是采用圆弧浅腔叶轮和一个能随之转动的刮板,旋转的刮板能将附着在叶片上的料粒挂落清除,能解决粉粒料在叶片上粘接的问题。使定量供料和排料更加顺畅,比较适用于容易导致堵塞的粉粒体,能提供150-5000mm的各种尺寸的方形和圆形口径。【电话/微信咨询:陈经理18068546632】 (GBS)刮板式旋转阀/卸料阀/星型卸料器适用于具有吸湿粘性和带有静电吸附性的粉粒物料、物料架桥结块。 阀体下部的旋转刮板自动将附在转子料斗内的物料刮落。 阀体上开有清理口,便于定期清除旋转阀内部的物料,设备带扭力保护器。 提供链驱动、马达直连驱动。 材质:碳钢、不锈钢、陶瓷、合金系列等。按客户需求定制。【电话/微信咨询:陈经理18068546632】 刮板式自清洁旋转阀/卸料阀,包括电机和壳体,其特征在于弧形叶轮和旋转刮板,弧形叶轮安装在壳体内部,弧形叶轮通过电机驱动;旋转刮板设置在弧形叶轮的下方,刮板卸料阀旋转刮板的顶部与弧形叶轮的弧面相接触,卸料阀旋转刮板与弧形叶轮之间通过壳体外的齿轮传动机构进行同步反向转动。 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询刮板式旋转阀》 For powder particles with high moisture adhesion due to humidity and poor flowability due to static electricity, it is very easy to bridge or adhere and fill the cavity between the blades of the rotary valve without falling off and being discharged, which "sticks" the leaf cavity and brings great difficulties to the operation of pneumatic conveying and rotary feeders. The scraper type rotary valve/discharge valve provided by Changzhou Tongdeli is characterized by using a curved shallow cavity impeller and a rotating scraper. The rotating scraper can remove the particles attached to the blades and solve the problem of powder particles sticking to the blades. Make quantitative feeding and discharging smoother, more suitable for powder particles that are prone to clogging, and can provide various sizes of square and circular diameters ranging from 150-5000mm. (GBS) Scraper type rotary valve/discharge valve/star shaped unloader is suitable for powder materials with hygroscopic viscosity and electrostatic adsorption, as well as material bridging and agglomeration. The rotating scraper at the bottom of the valve body automatically scrapes off the material attached to the rotor hopper. There is a cleaning port on the valve body for regular removal of materials inside the rotary valve, and the equipment is equipped with a torque protector. Provide chain drive and motor direct drive. Materials: carbon steel, stainless steel, ceramics, alloy series, etc. Customize according to customer needs. Scraper type self-cleaning rotary valve/discharge valve, comprising a motor and a housing, characterized by an arc-shaped impeller and a rotating scraper. The arc-shaped impeller is installed inside the housing and is driven by a motor; The rotating scraper is set below the arc-shaped impeller, and the top of the scraper discharge valve rotating scraper is in contact with the arc-shaped surface of the impeller. The rotating scraper of the discharge valve and the arc-shaped impeller rotate synchronously and in reverse through a gear transmission mechanism outside the housing.查看详情 +

-

【替代-全球一线品牌 科倍*Coper**】德国旋转阀/ 进口旋转阀,科倍龙旋转阀,Coperi**旋转阀,德国旋转阀,高端品牌旋转阀

产品介绍常州同得利拥有多年的研发生产/定制卸料阀旋转阀的经验,专 业替代进口德国品牌科倍龙Coperio*旋转阀,我公司专 业生产(B)GFY、YJD系列关风机(关风器)、星型卸料器、DS系列电动锁气器、DN型旋转阀,快开阀、清洁阀、风送式旋转阀等产品。广泛应用于粮食、饲料、石油化工、制药、淀粉、油脂、化工干燥、除尘、冶金、环保、电子、煤炭、建筑、电力机械等行业设备上。用于固体粒料、粉料、超微粉体在气力输送及管网正负压状态下的卸料。 公司在强化企业管理的基础上,依靠科技进步提高技术含量,先进的生产加工设备,领 先的管理理念,高素质的员工团队,有效的质量保障体系和完善的售后服务,为制造高品质的产品提供可靠的保证,极大的满足了各行业的需求,深受广大客户的信赖。 进口品牌价格贵,交期长怎么办?找国产替代,选大品牌-国盛商标常州同得利,专 利技术,匠心质造。【电话/微信咨询:陈经理18068546632】 以下【同得利】都可以替代 德国Coperio*科倍龙旋转阀: 德国科倍*ZRD旋转阀:应用于粉料的卸料和计量阀,1.5巴(21psi)系统压力和压差。 德国科倍*ZXD旋转阀:应用于粉料的底吹式,将散料喂入到气力输送系统中,1.5巴(21psi)系统压力和压差。 德国Coperi** 科倍*ZVB/ZVD旋转阀:适用于粒料的卸料阀,1.5巴(21psi)系统压力和压差。 德国Coperi** 科倍*旋转阀ZHD:适用于粉料的卸料和计量阀,增大入口的铸铁阀,尤其适用于排料应用,0.8 barg (12 psi) 系统和压差,聚四氟乙烯密封,无需气流冲洗。 德国Coperi** 科倍*ZKD旋转阀:适用于粉料的卸料和计量阀,矩形连接法兰的坚硬壳体,1.5巴(21psi),系统压力和压差,通过吹洗密封和物料掉落口将物料和轴承隔开。【电话/微信咨询代替方案:陈经理18068546632】 德国Coperi** 科倍*ZVH旋转阀:粒料高压卸料阀,几何形防切料入口可带料启动,3.5巴(51psi)系统压力和压差,带有12个转子腔和轴向密封的高压转子。 德国Coperi** 科倍*ZXQ旋转阀:适用于粉料的高压底吹式旋转阀,3.5巴(51psi)系统压力和压差。 德国Coperi** 科倍*旋转阀ZFD:吹除式阀门用于CIP执行的粉料,1.5 barg (21 psi)系统压力和压差。 德国Coperi** 科倍*MD旋转阀:应用于难处理物料的锁气阀,适用粉料、颗粒和磨料的卸料阀门,可承受严酷的冲击力,承受温度可达121o C[+250o F],1.4 巴(g) [20 psi(g)]。【电话/微信咨询代替方案:陈经理18068546632】 科倍*BT旋转阀:应用于研磨和烘焙卸料锁气旋转阀,经常应用于粘性应用,且能防止物料在转子腔中积聚,其配置提高了转子的自清洁功能,因而使得可在狭窄空间内安装。0.8 bar(g) [12 psi(g)] 压差,聚四氟乙烯复合密封,空气吹扫。 德国Coperi** 科倍*MD 1820 旋转阀:常用于难处理的物料,适用于粉料、颗粒和磨料的卸料阀,适用于重负荷和严苛的应用环境,可抵抗严苛的冲击力,承受高温达121o C [+250o F],1.4 巴(g) [20 psi(g)]。 德国Coperi** 科倍*卫生级旋转阀:应用于食品配方输送的旋转阀,必须满足卫生和高可靠性的要求。 我公司始终坚持“质量第 一、用户至 上”的宗旨,服务于社会,诚信于业界,竭诚欢迎世界各地的业界好友光临指导,洽谈合作。 《扫二维码-添加 陈经理 微信-咨询代替方案》 【部分客户需求】 1、替代科蓓隆:DN250.输送量10吨/小时,密封压力1.5BAR(G),DN200.输送量5吨/小时,密封压力1.6BAR(G)物料塑料粒子。 2、替代科倍隆CRD320.1-21-SS高度500容积21L,物料:PVC糊树脂粉料,堆积比重参照0.4~0.6t/m3.供料器能力按年平均产量推算约3t/h,物料温度<50℃。原设备口径 DN300.设备进出料口法兰端面间距500mm,电机功率 0.55KW,要求对设备整机进行替换。 3、对标科倍隆ZVB系列,出口用,物料:化工颗粒物料,400kg/h,误差精度要求比较高。 4、替代科倍隆ZKD 400.1-35-GC,物料:纤维素颗粒。【电话/微信咨询代替方案:陈经理18068546632】 5、替代科倍隆ZVH系列,物料石油树脂、橡胶粉末,粉料,每小时1200公斤,负压-0.095. 6、替代科倍隆ZFD系列,物料白糖,有负压状态,需要防卡和气密封型。 7、替代科倍隆ZXD 300.1-25-SC-DB4.物料粉料,钾肥。 8、客户以前用的科倍隆,现在需要国产化,物料:三氯化锂,并且需要破碎,高密封不能进空气,耐腐蚀,破碎至小于20~30mm。 9、客户以前用的科倍隆,现在需要国产化,食品级旋转下料阀(快拆易清洗),DN200旋转阀,物料名称 麦芽糖醇,颗粒物,40℃,物料含水<1%,物料粒度 10目,堆积密度(g/cm³) 0.8.物料接触部分材质为食用级SUS304.变频电机,粉尘防爆。 10、客户想用国产品牌,替代科倍隆ZXD 250 1-12-SC-DP3.物料煤粉。 11、客户以前用的科倍隆,现在需要国产化,原科倍隆型号ZRD 630.1-172-GC-DP1 1bar,450℃,水泥行业用。 12、客户以前用的科倍隆MD 1820系列,现在需要国产化,高压1.8MPa,颗粒8-12mm,生物质颗粒。【电话/微信咨询代替方案:陈经理18068546632】 13、客户想用国产品牌,替代科倍隆ZRD系列,粉体,叶轮和内衬都需要碳化钨,输送物料0-5kg/min,密度在0.8-2之间,颗粒度粉料2-3mm 。 14、客户之前用科倍隆ZVD系列,现在需要换成国产品牌,物料:炭黑粉料,锁气卸灰,负压,圆口200管径,6-8L,需要防爆型。查看详情 +

-

【正压输送-高密封】风送式旋转阀/ 锁风旋转阀,风送式卸料阀,密封旋转阀,气力输送旋转阀,正压旋转阀

产品介绍星型旋转阀常用在气力输出系统中。对于压力输出系统或负压输出系统,星型旋转阀可以均匀、连续地向输料管供料,以保证气力输出管内的气、固态比较稳定,从而使气力输送能正常工作,同时又能将旋转阀的上、下部气压隔断而起到锁气作用。因此,星型旋转阀是气力输送系统中常用的重要设备。 Star shaped rotary valves are commonly used in pneumatic output systems. For pressure output systems or negative pressure output systems, star shaped rotary valves can uniformly and continuously supply material to the conveying pipe to ensure that the gas and solid in the pneumatic output pipe are relatively stable, so that the pneumatic conveying can work normally. At the same time, they can also block the upper and lower air pressure of the rotary valve and play a role in air locking. Therefore, the star shaped rotary valve is an important equipment commonly used in pneumatic conveying systems. 正压稀相输送的介质一般采用空气或氮气,动力提供一般由罗茨鼓风机提供,氮气输送时则有制氮机进行提供。罗茨鼓风机的稀相输送时,物料在管道中呈悬浮状态,输送距离可以达百米,气流速度较高。 由于系统处于正压,所以密封性要求很高,若有一丝泄漏就会造成供料端或者整个系统的粉尘外溢;系统物料采用吹送式。【电话/微信咨询:陈经理18068546632】 风送式旋转阀: 针对物料粘接,风力直吹转子清理物料。 主要材质:碳钢、不锈钢304-316、钛合金、铝合金、各种合金、陶瓷、尼龙系列等。 气密封装置:高精度密封锁气,防止物料在输送过程中的泄漏,确保系统的正常运行。【电话/微信咨询:陈经理18068546632】 轴承外置式:有效的防止粉尘侵入轴承,增大设备适应较高温度的使用范围。 驱动方式:链驱动/马达直连驱动口。 动力配置:摆线针轮减速机、Y系列电机(可按客户指定动力配置)。【电话/微信咨询:陈经理18068546632】 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。 【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询正负压输送旋转阀》 部分客户需求: 1、替代意大利威埃姆,物料:动物饲料里面的预混料,阀体材质:不锈钢304;阀板材质:不锈钢304;带瓜片;转速:20rpm/min;功率0.75kw,非防爆电机,380V,50Hz;硬齿面减速电机,IE3能效等级电机;带轴承端盖保护;CE认证。 2、旋转给料阀:DN150.物料名称:抗氧剂,物料堆积密度:400~600kg/m3.工况:气力输送,工作温度:50°C,与物料接触材质CF8/SS304.输送能力0.3~0.35T/h,主体结构:开式叶轮,轴气封,轴承外置,背包式,容积效率:45%,叶轮转速18rpm。 3、火力发电厂在省煤器出口、SCR脱硝入口段,抽取部分烟气进行高温烟气的除尘。输灰用罗茨风机、工频旋转给料阀,现场除尘装置已配置收灰的储灰罐,需要在储灰缓冲罐下加装正压稀相气力输送系统。烟气温度:在300∽400℃范围内;输送介质:烟气中的粉煤灰;输送能力:输送容积0.7∽2m3/h,按不小于2m3/h设计选型;输送粉煤灰的重量约1600kg/h。【电话/微信咨询:陈经理18068546632】 4、物料:饲料颗料,正压输送,500公斤/小时,变频,锁气功能,出口到国外需要CE认证。 5、物料:生物质颗粒,直径5mm、长度40mm以下,正压气力输送,50kg/h。 6、水硫酸铝粉末定量稳定输送,每小时60公斤左右,微正压,无氧无水环境要求能通过DCS自动控制。 7、物料:板材行业的砂光粉,配罗茨风机用,正压输送,进口360*280高400.每小时2立方。 8、物料:输送催化剂,正压气力输送,6~8吨/小时,温度在500度左右,配水冷耐高温型。 9、粉料,储料罐小罐输送到大罐,正压输送,每小时输送量12吨,要气密封,防轴两端漏料。【电话/微信咨询:陈经理18068546632】 10、化肥助剂粉料,卸料量五百公斤/小时,密度0.8.正压输送,变频,需要锁气功能。 11、物料:铝粉,正压输送,DN200.伺服电机。 12、物料:塑料粉尘 正压输送 末端除尘器锁气卸料用,需求:低泄漏率的锁气卸灰阀。 13、替代泽普林旋转阀,物料:糖粉面粉,风送有正压和负压,DN150.DN200.DN300.DN500. 14、物料:草铵膦粉料,正压6000-9000Pa,密封锁气,防堵型DN200. 15、DN150不锈钢关风机,正压输送食品粉体,旋转阀需要抛光,配清洗型可以定期清理,侧开门式。【电话/微信咨询:陈经理18068546632】 16、食品粉料,正压输送用,食品级旋转阀,气密封,要清洗型,输送量1.5T/h。 17、输送物料:颗粒食用盐,输送量 5T/h,快拆式,材质 304.法兰标准 GB,SEW减速机;设备用途,正压风力输送使用;输送设计压力:50Kpa。 The medium for positive pressure dilute phase transportation is generally air or nitrogen, and the power supply is usually provided by a Roots blower. When transporting nitrogen, a nitrogen generator is used. During the dilute phase conveying of Roots blower, the material is suspended in the pipeline, with a conveying distance of up to 100 meters and a high airflow velocity. Due to the positive pressure of the system, high sealing requirements are required. Any slight leakage can cause dust to overflow from the feeding end or the entire system; The system materials are blown. Pneumatic rotary valve: For material bonding, the rotor is blown directly by wind to clean the material. Main materials: carbon steel, stainless steel 304-316. titanium alloy, aluminum alloy, various alloys, ceramics, nylon series, etc. Airtight sealing device: high-precision sealing and gas locking to prevent material leakage during transportation and ensure the normal operation of the system. External bearing: effectively prevents dust from entering the bearing and increases the equipment's adaptability to higher temperatures. Drive mode: chain drive/motor directly connected to the drive port. Power configuration: Cycloid pinwheel reducer, Y series motor (can be configured according to customer's specified power).查看详情 +

-

【锂电/化工/制药】全尼龙卸料阀-防金属防腐防粘/ 全尼龙旋转阀,尼龙卸料器,尼龙卸料阀,防腐蚀卸料阀

产品介绍全尼龙卸料阀用于不可接触金属物料的卸料。箱体、叶轮以及端盖,都采用整块尼龙铣削加工,结构牢靠,运行无噪音,相较于陶瓷星型卸料阀,可以节省成本,是锂电行业新宠。The all nylon discharge valve is used for unloading non-contact metal materials. The box body, impeller, and end cover are all processed by whole piece nylon milling, with a reliable structure and noiseless operation. Compared with ceramic star shaped discharge valves, it can save costs and is the new favorite of the lithium battery industry.全尼龙卸料阀采用加厚叶轮设计,与壳体配合间隙小,结构精密,使用过程中不易漏风不易漏料,防堵耐用。密封优越,用感无忧:结构稳定,密封性能良好。可用于粉料、小颗粒物料,在正负极压差吸送过程中将物料分离排出。Excellent sealing, worry free use: stable structure, good sealing performance. Can be used for powder and small particle materials to separate and discharge materials during the positive and negative pressure difference suction process.尼龙星型阀特点:改性尼龙比普通尼龙更耐磨、耐高温。适用于锂电正极材料输送,高镍三元材料,磷酸铁锂。阀体、端盖外表面采用304.物料接触8-10mm氧化铝陶瓷工艺等。都可以满足工况耐磨,耐温尤为突出。尼龙星型阀技术研发于2016年,批量生产于2018年,2020年更新第4代尼龙星型旋转阀,目前有尼龙星型旋转阀专 利。【电话/微信咨询:陈经理18068546632】全尼龙卸料阀特点:1、良好的耐腐蚀性能:尼龙卸料阀的材料能够很好地抵抗酸、碱等化学介质的侵蚀,具有优异的耐腐蚀性能,适用于各种介质的输送。2、良好的耐磨性能:尼龙材料具有优异的耐磨性,尼龙卸料阀的使用可以有效减少阀门的磨损程度,提高阀门的使用寿命。3、良好的耐高温性能:所采用的材料具有良好的高温稳定性,可在高温条件下安全使用。它是一种用于输送介质的可靠材料。4、良好的气密封性能:壳体与旋转叶轮之间的间隙,实现了锁气功能,避免了气体泄露的问题,全尼龙卸料阀的两端采用了气密装置,确保了阀的密封性。尼龙旋转卸料的使用注意事项:1、卸料阀内衬尼龙在安装时应注意对阀门进行定位,防止因阀门定位不准而引起的磨损和腐蚀。2、使用卸料阀内衬尼龙时,应注意其材料的耐压性能,以保证使用安全。3、在卸料阀内衬尼龙的使用过程中,应避免使用过于剧烈的撞击力,防止材料损坏。【电话/微信咨询:陈经理18068546632】常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粉料、超微粉体等。 《扫二维码-添加 陈经理 微信-咨询卸料阀》Characteristics of Nylon Star Valve: Modified Nylon is more wear-resistant and heat-resistant than ordinary Nylon. Suitable for transporting lithium-ion cathode materials, high nickel ternary materials, and lithium iron phosphate. The outer surface of the valve body and end cap is made of 304 material contact 8-10mm alumina ceramic technology, etc. All of them can meet the requirements of wear-resistant and temperature resistant working conditions.The nylon star shaped valve technology was developed in 2016 and mass-produced in 2018. The fourth generation nylon star shaped rotary valve was updated in 2020. and there is currently a patent for nylon star shaped rotary valve.Characteristics of all nylon discharge valve:1. Good corrosion resistance:The material of nylon discharge valve can resist the erosion of chemical media such as acid and alkali well, and has excellent corrosion resistance, suitable for the transportation of various media.2. Good wear resistance:Nylon material has excellent wear resistance, and the use of nylon discharge valves can effectively reduce the degree of valve wear and improve the service life of valves.3. Good high temperature resistance:The materials used have good high-temperature stability and can be safely used under high temperature conditions. It is a reliable material used for conveying media.4. Good gas sealing performance:The gap between the shell and the rotating impeller achieves gas locking function, avoiding gas leakage problems. The two ends of the all nylon discharge valve are equipped with airtight devices to ensure the sealing of the valve.查看详情 +