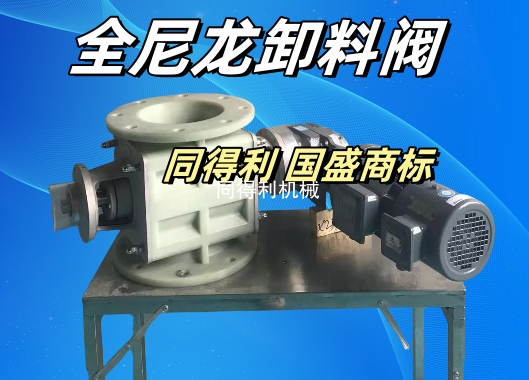

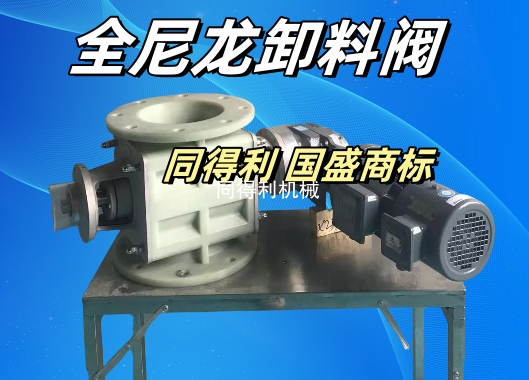

【锂电/化工/制药】全尼龙卸料阀-防金属防腐防粘

【锂电/化工/制药】全尼龙卸料阀-防金属防腐防粘

| 参数名称 | 参数值 |

|---|---|

| 行业 | 锂电,化工,制药,石英粉 |

| 卸料阀主要结构 | 壳体,叶轮,端盖 |

| 材质 | 改性尼龙 |

| 尼龙卸料阀特点 | 改性尼龙比普通尼龙更耐磨,更耐高温 |

| 品牌 | 常州同得利,国盛商标 |

| 常规型号 | DN50,DN100,DN150,DN200,DN250,DN300,DN350,DN400,DN450,DN500 |

| 联系电话(陈经理) | 18068546632 |

全尼龙卸料阀用于不可接触金属物料的卸料。箱体、叶轮以及端盖,都采用整块尼龙铣削加工,结构牢靠,运行无噪音,相较于陶瓷星型卸料阀,可以节省成本,是锂电行业新宠。

The all nylon discharge valve is used for unloading non-contact metal materials. The box body, impeller, and end cover are all processed by whole piece nylon milling, with a reliable structure and noiseless operation. Compared with ceramic star shaped discharge valves, it can save costs and is the new favorite of the lithium battery industry.

全尼龙卸料阀采用加厚叶轮设计,与壳体配合间隙小,结构精密,使用过程中不易漏风不易漏料,防堵耐用。

密封优越,用感无忧:结构稳定,密封性能良好。可用于粉料、小颗粒物料,在正负极压差吸送过程中将物料分离排出。

Excellent sealing, worry free use: stable structure, good sealing performance. Can be used for powder and small particle materials to separate and discharge materials during the positive and negative pressure difference suction process.

尼龙星型阀特点:改性尼龙比普通尼龙更耐磨、耐高温。适用于锂电正极材料输送,高镍三元材料,磷酸铁锂。阀体、端盖外表面采用304.物料接触8-10mm氧化铝陶瓷工艺等。都可以满足工况耐磨,耐温尤为突出。

尼龙星型阀技术研发于2016年,批量生产于2018年,2020年更新第4代尼龙星型旋转阀,目前有尼龙星型旋转阀专 利。【电话/微信咨询:陈经理18068546632】

全尼龙卸料阀特点:

1、良好的耐腐蚀性能:

尼龙卸料阀的材料能够很好地抵抗酸、碱等化学介质的侵蚀,具有优异的耐腐蚀性能,适用于各种介质的输送。

2、良好的耐磨性能:

尼龙材料具有优异的耐磨性,尼龙卸料阀的使用可以有效减少阀门的磨损程度,提高阀门的使用寿命。

3、良好的耐高温性能:

所采用的材料具有良好的高温稳定性,可在高温条件下安全使用。它是一种用于输送介质的可靠材料。

4、良好的气密封性能:

壳体与旋转叶轮之间的间隙,实现了锁气功能,避免了气体泄露的问题,全尼龙卸料阀的两端采用了气密装置,确保了阀的密封性。

尼龙旋转卸料的使用注意事项:

1、卸料阀内衬尼龙在安装时应注意对阀门进行定位,防止因阀门定位不准而引起的磨损和腐蚀。

2、使用卸料阀内衬尼龙时,应注意其材料的耐压性能,以保证使用安全。

3、在卸料阀内衬尼龙的使用过程中,应避免使用过于剧烈的撞击力,防止材料损坏。【电话/微信咨询:陈经理18068546632】

常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粉料、超微粉体等。

《扫二维码-添加 陈经理 微信-咨询卸料阀》

Characteristics of Nylon Star Valve: Modified Nylon is more wear-resistant and heat-resistant than ordinary Nylon. Suitable for transporting lithium-ion cathode materials, high nickel ternary materials, and lithium iron phosphate. The outer surface of the valve body and end cap is made of 304 material contact 8-10mm alumina ceramic technology, etc. All of them can meet the requirements of wear-resistant and temperature resistant working conditions.

The nylon star shaped valve technology was developed in 2016 and mass-produced in 2018. The fourth generation nylon star shaped rotary valve was updated in 2020. and there is currently a patent for nylon star shaped rotary valve.

Characteristics of all nylon discharge valve:

1. Good corrosion resistance:

The material of nylon discharge valve can resist the erosion of chemical media such as acid and alkali well, and has excellent corrosion resistance, suitable for the transportation of various media.

2. Good wear resistance:

Nylon material has excellent wear resistance, and the use of nylon discharge valves can effectively reduce the degree of valve wear and improve the service life of valves.

3. Good high temperature resistance:

The materials used have good high-temperature stability and can be safely used under high temperature conditions. It is a reliable material used for conveying media.

4. Good gas sealing performance:

The gap between the shell and the rotating impeller achieves gas locking function, avoiding gas leakage problems. The two ends of the all nylon discharge valve are equipped with airtight devices to ensure the sealing of the valve.

Construction case

Related products