我们只做高品质的产品

公司以诚信、实力和产品质量获得业界的认可,欢迎各界朋友莅临参观,指导和业务洽谈

-

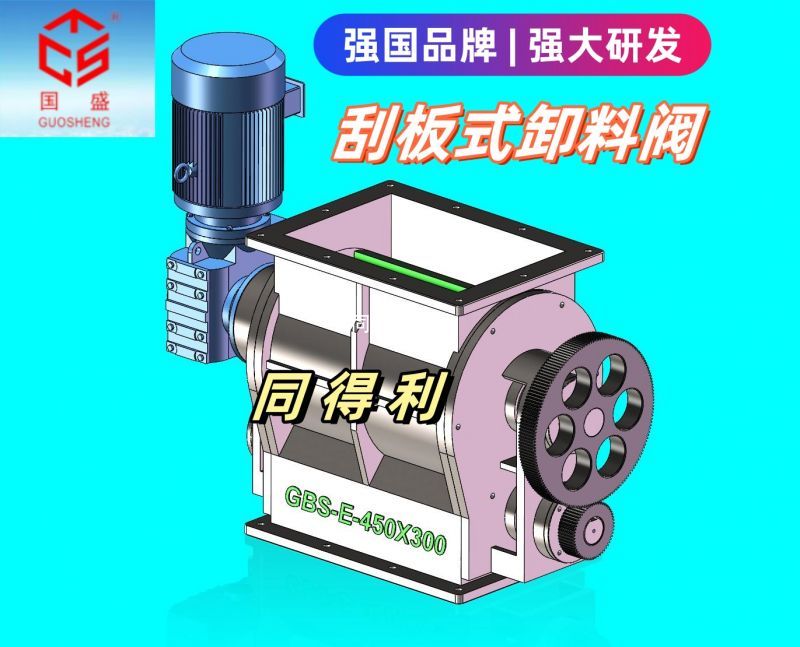

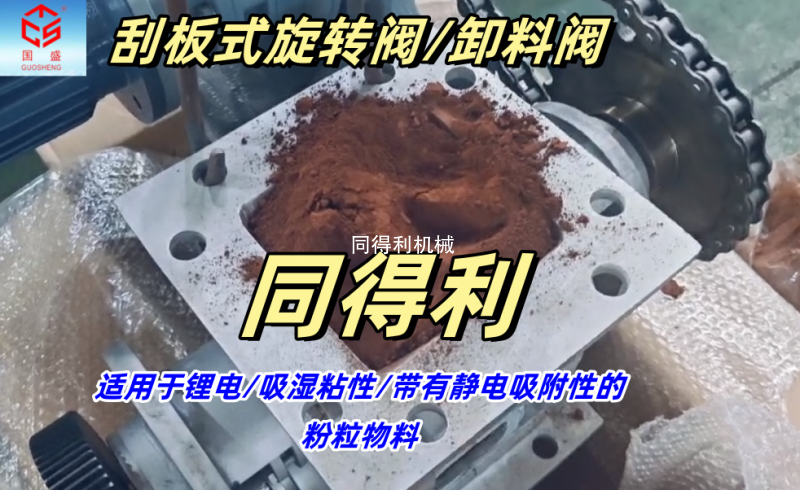

【粘性物料】刮板式旋转阀-高端品牌/ 吸湿粘性料卸料阀,刮板卸料器,刮板式旋转阀,自清理旋转阀,自清洁卸料器,钢厂旋转阀

产品介绍对于由于潮湿高水分黏附的粉粒料和由于静电易附着流动性差的粉粒料,非常容易架桥或粘附填充在旋转阀的叶片间空腔中不脱落排卸下来,将叶子空腔“糊”住,给气力输送和旋转供料器操作带来很大困难。常州同得利提供的刮板式旋转阀/卸料阀,其特点是采用圆弧浅腔叶轮和一个能随之转动的刮板,旋转的刮板能将附着在叶片上的料粒挂落清除,能解决粉粒料在叶片上粘接的问题。使定量供料和排料更加顺畅,比较适用于容易导致堵塞的粉粒体,能提供150-5000mm的各种尺寸的方形和圆形口径。【电话/微信咨询:陈经理18068546632】 (GBS)刮板式旋转阀/卸料阀/星型卸料器适用于具有吸湿粘性和带有静电吸附性的粉粒物料、物料架桥结块。 阀体下部的旋转刮板自动将附在转子料斗内的物料刮落。 阀体上开有清理口,便于定期清除旋转阀内部的物料,设备带扭力保护器。 提供链驱动、马达直连驱动。 材质:碳钢、不锈钢、陶瓷、合金系列等。按客户需求定制。【电话/微信咨询:陈经理18068546632】 刮板式自清洁旋转阀/卸料阀,包括电机和壳体,其特征在于弧形叶轮和旋转刮板,弧形叶轮安装在壳体内部,弧形叶轮通过电机驱动;旋转刮板设置在弧形叶轮的下方,刮板卸料阀旋转刮板的顶部与弧形叶轮的弧面相接触,卸料阀旋转刮板与弧形叶轮之间通过壳体外的齿轮传动机构进行同步反向转动。 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询刮板式旋转阀》 For powder particles with high moisture adhesion due to humidity and poor flowability due to static electricity, it is very easy to bridge or adhere and fill the cavity between the blades of the rotary valve without falling off and being discharged, which "sticks" the leaf cavity and brings great difficulties to the operation of pneumatic conveying and rotary feeders. The scraper type rotary valve/discharge valve provided by Changzhou Tongdeli is characterized by using a curved shallow cavity impeller and a rotating scraper. The rotating scraper can remove the particles attached to the blades and solve the problem of powder particles sticking to the blades. Make quantitative feeding and discharging smoother, more suitable for powder particles that are prone to clogging, and can provide various sizes of square and circular diameters ranging from 150-5000mm. (GBS) Scraper type rotary valve/discharge valve/star shaped unloader is suitable for powder materials with hygroscopic viscosity and electrostatic adsorption, as well as material bridging and agglomeration. The rotating scraper at the bottom of the valve body automatically scrapes off the material attached to the rotor hopper. There is a cleaning port on the valve body for regular removal of materials inside the rotary valve, and the equipment is equipped with a torque protector. Provide chain drive and motor direct drive. Materials: carbon steel, stainless steel, ceramics, alloy series, etc. Customize according to customer needs. Scraper type self-cleaning rotary valve/discharge valve, comprising a motor and a housing, characterized by an arc-shaped impeller and a rotating scraper. The arc-shaped impeller is installed inside the housing and is driven by a motor; The rotating scraper is set below the arc-shaped impeller, and the top of the scraper discharge valve rotating scraper is in contact with the arc-shaped surface of the impeller. The rotating scraper of the discharge valve and the arc-shaped impeller rotate synchronously and in reverse through a gear transmission mechanism outside the housing.查看详情 +

-

【链驱动】正压输送旋转阀-粉体/ 粉体旋转阀,粉料旋转阀,正压旋转阀,气力输送旋转阀

产品介绍正压稀相气力输送系统是采用罗茨风机或者罗茨空压泵作为动力源。利用空气动能作为输送介质,物料以比较高的速度并以分散悬浮的状态在管道中输送。输送的压力一般根据工况条件不同可在几千帕到几百千帕范围内调整。 利用气体动压,物料以较高速度在输送管道中前进(8m/s-25m/s ),输送压力沿输送管道逐渐降低; 连续输送,输送流态、输送压力与输送速度、料气比基本保持稳定; 在一定情况下,输送距离较正压密相短、较负压稀相长; 输送过程中,罗茨鼓风机的出口空气温度较高; 为了防止串气,系统需要配备密闭性较好的旋转供料阀/旋转阀/星型卸料阀/关风机卸料器。【电话/微信咨询:陈经理18068546632】 正压输送旋转阀/风送式旋转阀主要用于化工、食品、药材、锂电、塑料原料输送。 针对物料粘接,风力直吹转子清理物料。 主要材质:不锈钢304-316、钛合金、铝合金、各种合金。 《扫二维码-添加 陈经理 微信-咨询链驱动正压旋转阀》 The positive pressure dilute phase pneumatic conveying system uses Roots blower or Roots air pump as the power source. Using air kinetic energy as a conveying medium, materials are transported in pipelines at relatively high speeds and in a dispersed and suspended state. The conveying pressure can generally be adjusted within the range of several thousand pascals to several hundred kilopascals according to different working conditions. Using gas dynamic pressure, the material advances at a high speed in the conveying pipeline (8m/s-25m/s), and the conveying pressure gradually decreases along the conveying pipeline; Continuous conveying, the conveying flow state, conveying pressure and speed, and material gas ratio remain basically stable; In certain circumstances, the conveying distance is shorter than that of the positive pressure dense phase and longer than that of the negative pressure dilute phase; During the conveying process, the outlet air temperature of the Roots blower is relatively high; In order to prevent air leakage, the system needs to be equipped with a well sealed rotary feeding valve/rotary valve/star shaped discharge valve/shut-off fan discharge device. Positive pressure conveying rotary valve/pneumatic rotary valve is mainly used for conveying chemical, food, medicinal materials, lithium batteries, and plastic raw materials.查看详情 +

-

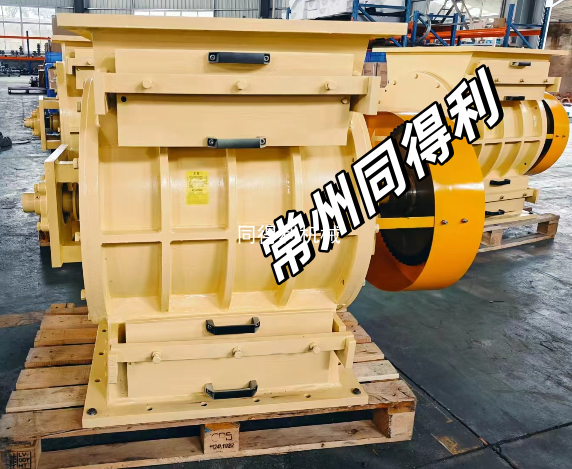

【链驱动】刚性旋转阀-钢厂/电厂/矿山/水泥/ 钢厂旋转阀,电厂旋转阀,矿山旋转阀,刚性旋转阀,刚性卸料阀

产品介绍刚性旋转阀/卸料阀/旋转卸料器/旋转供料器常用于难处理的物料, 适用于粉料、颗粒和磨料(坚硬物料、块状物料、高温物料)的旋转卸料阀。大型号旋转阀,为高流量设计,适用于重负荷和严苛的应用环境,压力可达2 bar(g) [20 psi(g)]可抵抗严苛的冲击力,承受高温达300℃,压力范围:1.4 巴(g) [20 psi(g)]轴封:聚四氟乙烯复合密封,空气吹扫。外侧轴承:通过密封和物料掉落口将物料和轴承隔开。 刚性旋转阀主要用于钢厂、电厂、水泥、矿山等行业。叶轮稳定性好、圆滑过度、无夹角、扭矩更大。【电话/微信咨询:陈经理18068546632】 1、结构紧凑:采用行星转动原理、纯铜电机,输入输出在同一轴线上,而且有与电机直联一体的独特性,体积小,重量轻,因而结构紧凑造型美观新样。 2、耐磨性高:运行可靠平稳,噪音低,故障少,寿命长,耐磨性高。 3、过载能力强:卸料器具有过载能力强,耐冲击惯性力矩小,适用于启动频繁和正反转。 4、使用寿命长:轴承、齿箱、远离阀体避免高温灰尘的影响,前后密封性能好,防止灰尘外泄,延长机动件,润滑系统的使用寿命。 5、支持定制/替代进口品牌:用户如有特殊规格要求,可以按照客户要求定做。【电话/微信咨询:陈经理18068546632】 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询刚性旋转阀》 Rigid rotary valves/discharge valves/rotary unloaders/rotary feeders are commonly used for difficult to handle materials, suitable for rotary discharge valves of powders, particles, and abrasives (hard materials, block materials, high-temperature materials). Large rotary valve, designed for high flow, suitable for heavy loads and harsh application environments, with a pressure of up to 2 bar (g) [20 psi (g)], can resist harsh impact forces, withstand high temperatures up to 300 ℃, pressure range: 1.4 bar (g) [20 psi (g)], shaft seal: PTFE composite seal, air blowing. Outer bearings: Separate materials and bearings through seals and material drop ports. Rigid rotary valves are mainly used in industries such as steel mills, power plants, cement, and mining. The impeller has good stability, smooth transition, no angle, and greater torque. 1. Compact structure: Adopting the principle of planetary rotation and a pure copper motor, the input and output are on the same axis, and it has the unique feature of being directly connected to the motor. It is small in size and light in weight, resulting in a compact structure and beautiful appearance. 2. High wear resistance: reliable and stable operation, low noise, few faults, long service life, high wear resistance. 3. Strong overload capacity: The unloader has strong overload capacity, low impact resistance inertia moment, and is suitable for frequent starting and forward and reverse rotation. 4. Long service life: bearings, gearboxes, and valves are kept away from the valve body to avoid the influence of high temperature dust. The front and rear sealing performance is good, preventing dust leakage and extending the service life of motor components and lubrication systems. 5. Support customization/substitution of imported brands: If users have special specifications requirements, they can customize according to their needs.查看详情 +

-

【链驱动】高温清洗型旋转阀/ 滑杆式旋转阀,防卡防堵旋转阀,高温旋转阀,清洗型旋转阀

产品介绍根据物料输送和下料口的温度不同,因为温度对机体膨胀有影响,以及对轴承和油封系统不利,我厂设计了耐高温型外装式结构关风机旋转阀,它把运转部分与物料接触的箱体部分分离开来,可以安全地把轴承运转和油封系统不受高温影响而正常工作,此类产品不但耐高温,还可以针对吸湿性物料和金属性粉末的输送和卸料,具有很好的效果。因为这类物体有穿透性,穿透油封装置,物料进入轴承而损坏机械,正是有外装的特点,它不会和物料接触。 旋转阀主要结构:外壳金属;物料接触部分:内衬陶瓷(也可尼龙、四氟、特氟龙、聚氨酯、不锈钢、合金等)。针对物料粘接,风力直吹转子清理。快拆清理,快速复位。可拆卸叶轮:便于快速拆卸清洗旋转阀的物料接触面。驱动方式:链驱动/马达直连驱动。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询链驱动高温清洗型旋转阀》查看详情 +

-

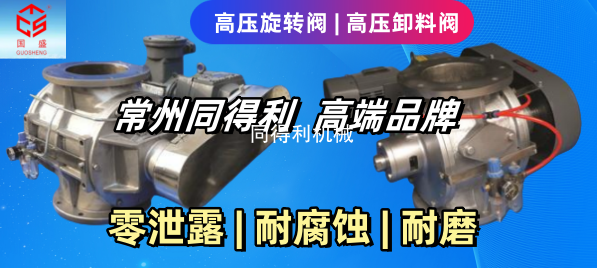

【链条传动】高压旋转阀-密封锁气/ 高压卸料阀,高压旋转阀,高压星型卸料器,高压锁气阀

产品介绍旋转阀的工作原理主要涉及电动机驱动减速机,通过联轴器或链轮使旋转阀的转子旋转。在旋转过程中,材料位于旋转叶片的空间内,叶片的旋转将材料带到排出口,材料的自重使其流入输送系统或储藏室。这种工作方式使得旋转卸料阀能够均匀、连续地向输料管供料,保证气力输出管内的气体和固体物质保持稳定,从而确保气力输送系统的正常工作。同时,旋转阀还具有锁气作用,能够隔断卸料阀上下部的气压。【电话/微信咨询:陈经理18068546632】 高压旋转阀主要用于化工,食品,药材,锂电原料输送。 针对有腐蚀物料、有害气体,实现零泄漏、耐腐蚀、耐磨。 高压旋转卸料阀主要材质:不锈钢、哈氏合金、钛合金、铝合金、各种合金。 常州同得利提供链驱动、直连驱动多种安装方式。 我公司始终坚持“质量第 一、用户至 上”的宗旨,服务于社会,诚信于业界,竭诚欢迎世界各地的业界好友光临指导,洽谈合作。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询链驱动高压旋转阀》 The working principle of a rotary valve mainly involves an electric motor driving a reducer, which rotates the rotor of the rotary valve through a coupling or sprocket. During the rotation process, the material is located in the space of the rotating blades, and the rotation of the blades brings the material to the discharge outlet. The self weight of the material causes it to flow into the conveying system or storage room. This working method enables the rotary discharge valve to uniformly and continuously feed the conveying pipe, ensuring that the gas and solid substances in the pneumatic output pipe remain stable, thereby ensuring the normal operation of the pneumatic conveying system. At the same time, the rotary valve also has a locking effect, which can block the air pressure at the upper and lower parts of the discharge valve. High pressure rotary valves are mainly used for transporting chemical, food, medicinal materials, and lithium battery raw materials. To achieve zero leakage, corrosion resistance, and wear resistance for corrosive materials and harmful gases. The main materials of high-pressure rotary discharge valve are stainless steel, Hastelloy, titanium alloy, aluminum alloy, and various alloys. Changzhou Tongdeli provides multiple installation methods for chain drive and direct drive. Our company always adheres to the principle of "quality first, customer first", serves society, and is honest in the industry. We sincerely welcome industry friends from all over the world to visit and guide us, and negotiate cooperation.查看详情 +

-

【链条传动】高温旋转阀>800度可定制/ 高温卸料阀,链条传动旋转阀,链驱动旋转阀,高温旋转阀

产品介绍高温旋转阀/水冷式旋转阀/高温卸料阀,其外壳、盖板、转子以及轴承部件都采用循环水冷却,密封材料和轴承部分能承受在高温下正常运转,适用于钢厂、电厂、矿山、水泥、锅炉、锂电、化工、污泥逢烧、桔杆逢烧、窑底出料、锅炉排料、真空杀菌等行业。也可根据用户要求进行结构设计制造,确保安全正常工作。叶轮主轴采用全 面通水降温,避免高温形变,影响同心度。【电话/微信咨询:陈经理18068546632】 需求1:变频给料阀/高温旋转阀:焙烧车间,用途:控制硫磺仓内硫磺的供给量。物料堆密度 t/m³:1.5.输送量 t/h:5.尺寸:DN200.阀门高度/mm:H≈420.阀体(上下壳体)材质:304.叶轮:304.物料温度:200~400℃,等级:10kv,380V/220V,50Hz。 需求2:粉体旋转阀,4英寸卡接口,DN100 316L材质 手动 物料是有制药用粉末,高温度200℃蒸汽灭菌。 需求3:物料:脱硫灰粉料,耐高温:400-500度,目前用的不锈钢材质。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询链驱动高温旋转阀》 High temperature rotary valve/water-cooled rotary valve/high temperature discharge valve, its shell, cover plate, rotor, and bearing components are all cooled by circulating water. The sealing material and bearing parts can withstand normal operation at high temperatures, and are suitable for industries such as steel mills, power plants, mines, cement, boilers, lithium batteries, chemical engineering, sludge co firing, orange rod co firing, kiln bottom discharge, boiler discharge, vacuum sterilization, etc. Structural design and manufacturing can also be carried out according to user requirements to ensure safe and normal operation. The impeller spindle adopts comprehensive water cooling to avoid high-temperature deformation and affect concentricity. Variable frequency feeding valve/high-temperature rotary valve: used in the roasting workshop to control the supply of sulfur in the sulfur silo. Material bulk density t/m ³: 1.5. Conveying capacity t/h: 5. Size: DN200. Valve height/mm: H ≈ 420. Valve body (upper and lower shells) material: 304. Impeller: 304. Material temperature: 200~400 ℃, grade: 10kV, 380V/220V, 50Hz. Powder rotary valve, 4-inch card interface, DN100 316L material manual material is pharmaceutical powder, high temperature 200 ℃ steam sterilization. Material: desulfurization ash powder, high temperature resistance: 400-500 degrees, currently using stainless steel material.查看详情 +

-

【吸湿性物料】刮板卸料阀-钢厂/电厂/水泥/矿山/ 粘性物料卸料阀,刮板旋转阀,刮板卸料阀,刮板卸料器,钢厂卸料阀

产品介绍(BGB)刮板式卸料阀/旋转阀/星型卸料器系列适用于具有吸湿粘性和带有静电吸附性的粉粒物料。 刮板卸料阀的阀体下部的旋转刮板自动将附在转子料斗内的物料挂落。 阀体上开有清理口,便于定期清除旋转阀内部的物料。 提供链驱动、马达直连驱动。 刮板卸料阀材质:碳钢、不锈钢系列等。【电话/微信咨询:陈经理18068546632】 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询刮板式卸料阀》 The (BGB) scraper type discharge valve/rotary valve/star shaped unloader series is suitable for powder materials with hygroscopic viscosity and electrostatic adsorption. The rotating scraper at the lower part of the valve body of the scraper discharge valve automatically hangs the material attached to the rotor hopper. There is a cleaning port on the valve body for regular removal of materials inside the rotary valve. Provide chain drive and motor direct drive. Material of scraper discharge valve: carbon steel, stainless steel series, etc.查看详情 +

-

【链驱动】碳钢卸料阀-耐磨/ 链条传动卸料阀,链驱动卸料阀,链驱动旋转阀,耐磨卸料阀

产品介绍卸料阀也称星型卸料阀、旋转阀、旋转给料阀、旋转供料器、喂料阀、分格轮,广泛应用于建材行业作为料仓的卸料装置。具有锁风和连续给料的双重作用。动力配置选用高质量减速电机。整体设计采用了国外先进设计思想,结构紧凑,维护方便,性能可靠。 安装要点:喂料阀只适合于水平安装。进口和出口法兰之间必须安装密封垫片(或石棉绳),以免漏料。进口和出口法兰之间必须安装密封垫片(或石棉绳),以免漏料。 机械和电气的安装工作完成以后检查以下各项:a) 所有的紧固螺钉均拧紧。b) 连接的完整性(轴端密封清扫用空气气路连接完毕)。c) 接电工作由专 业电工完成。初次启动必须不带物料,在确信回转下料阀转动无任何故障并且在机壳中的转子无启动噪音之后即可向系统供料。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询耐磨碳钢卸料阀》查看详情 +

-

【链驱动】偏置式旋转阀-发电厂/钢厂/矿山/水泥/ 链驱动旋转阀,链驱动卸料阀,偏置旋转阀,

产品介绍偏置式旋转阀适用于≤2kg/cm²系统压力或压差。 设置排气口(正压输送时选用)将叶轮旋转带出的气体通过排气口送至排气装置,提高填充效率。 防切料入口设计,即便上游充满物料也可安全启动。偏置式进出料口设计:减少了物料的破碎与损坏。 偏置式旋转阀主要用于钢厂、电厂、水泥、矿山原料输送。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询链驱动偏置式旋转阀》 Biased rotary valves are suitable for system pressures or pressure differentials of ≤ 2kg/cm ². Set up an exhaust port (selected for positive pressure conveying) to send the gas carried out by the impeller rotation to the exhaust device through the exhaust port, improving the filling efficiency. Anti cutting material inlet design ensures safe start-up even when the upstream is filled with materials. Offset inlet and outlet design: reduces material breakage and damage. Offset rotary valves are mainly used for conveying raw materials in steel mills, power plants, cement, and mines.查看详情 +