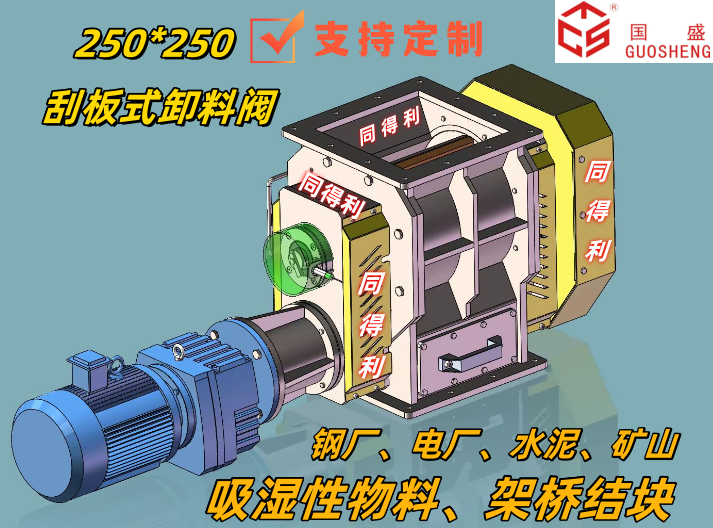

【粘性物料】刮板式旋转阀-高端品牌

【粘性物料】刮板式旋转阀-高端品牌

| 参数名称 | 参数值 |

|---|---|

| 品名 | 刮板式旋转阀,刮板卸料阀,刮板卸料器,粘性物料卸料阀,粘性料旋转阀,钢厂卸料阀,电厂卸料阀,水泥卸料阀,矿山卸料阀 |

| 输送物料 | 具有吸湿性和物料架桥结块,带有静电吸附性的粉粒物料 |

| 应用行业 | 钢厂、电厂、水泥、矿山、环保、锂电、化工、食品等 |

| 尺寸 | DN150 ~ DN4000,150*150 ~ 5000*4000,非标定制 |

| 材质 | 碳钢、不锈钢、陶瓷、合金等 |

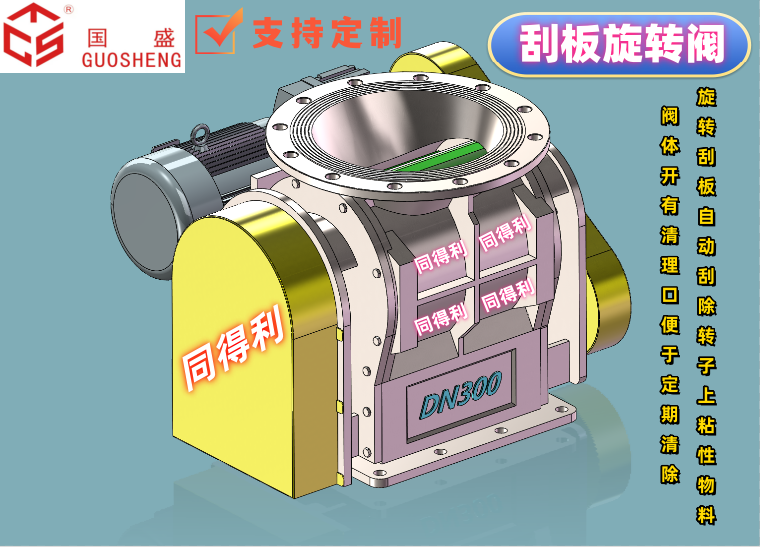

| 特点 | 旋转刮板自动清除转子上物料,自清理,自清洁 |

| 驱动方式 | 链驱动、马达直连驱动 |

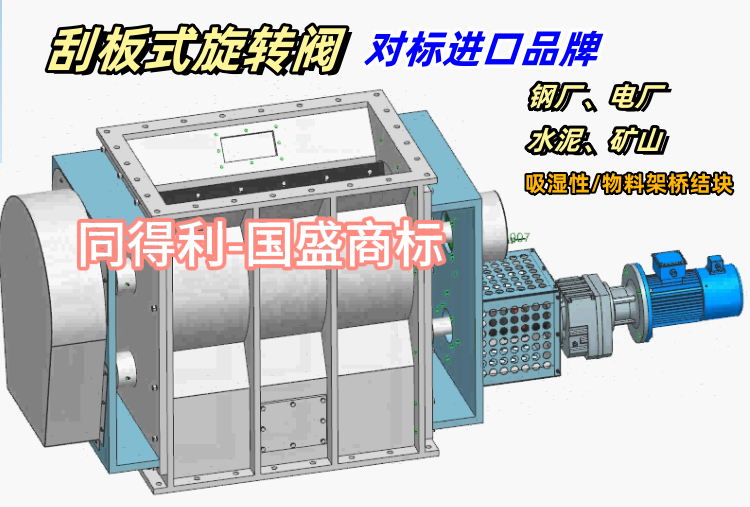

| 品牌 | 对标进口一线品牌,常州同得利,江苏同得利,国盛商标 |

| 联系电话(陈经理) | 18068546632 |

对于由于潮湿高水分黏附的粉粒料和由于静电易附着流动性差的粉粒料,非常容易架桥或粘附填充在旋转阀的叶片间空腔中不脱落排卸下来,将叶子空腔“糊”住,给气力输送和旋转供料器操作带来很大困难。常州同得利提供的刮板式旋转阀/卸料阀,其特点是采用圆弧浅腔叶轮和一个能随之转动的刮板,旋转的刮板能将附着在叶片上的料粒挂落清除,能解决粉粒料在叶片上粘接的问题。使定量供料和排料更加顺畅,比较适用于容易导致堵塞的粉粒体,能提供150-5000mm的各种尺寸的方形和圆形口径。【电话/微信咨询:陈经理18068546632】

(GBS)刮板式旋转阀/卸料阀/星型卸料器适用于具有吸湿粘性和带有静电吸附性的粉粒物料、物料架桥结块。

阀体下部的旋转刮板自动将附在转子料斗内的物料刮落。

阀体上开有清理口,便于定期清除旋转阀内部的物料,设备带扭力保护器。

提供链驱动、马达直连驱动。

材质:碳钢、不锈钢、陶瓷、合金系列等。按客户需求定制。【电话/微信咨询:陈经理18068546632】

刮板式自清洁旋转阀/卸料阀,包括电机和壳体,其特征在于弧形叶轮和旋转刮板,弧形叶轮安装在壳体内部,弧形叶轮通过电机驱动;旋转刮板设置在弧形叶轮的下方,刮板卸料阀旋转刮板的顶部与弧形叶轮的弧面相接触,卸料阀旋转刮板与弧形叶轮之间通过壳体外的齿轮传动机构进行同步反向转动。

常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。【电话/微信咨询:陈经理18068546632】

《扫二维码-添加 陈经理 微信-咨询刮板式旋转阀》

For powder particles with high moisture adhesion due to humidity and poor flowability due to static electricity, it is very easy to bridge or adhere and fill the cavity between the blades of the rotary valve without falling off and being discharged, which "sticks" the leaf cavity and brings great difficulties to the operation of pneumatic conveying and rotary feeders. The scraper type rotary valve/discharge valve provided by Changzhou Tongdeli is characterized by using a curved shallow cavity impeller and a rotating scraper. The rotating scraper can remove the particles attached to the blades and solve the problem of powder particles sticking to the blades. Make quantitative feeding and discharging smoother, more suitable for powder particles that are prone to clogging, and can provide various sizes of square and circular diameters ranging from 150-5000mm.

(GBS) Scraper type rotary valve/discharge valve/star shaped unloader is suitable for powder materials with hygroscopic viscosity and electrostatic adsorption, as well as material bridging and agglomeration.

The rotating scraper at the bottom of the valve body automatically scrapes off the material attached to the rotor hopper.

There is a cleaning port on the valve body for regular removal of materials inside the rotary valve, and the equipment is equipped with a torque protector.

Provide chain drive and motor direct drive.

Materials: carbon steel, stainless steel, ceramics, alloy series, etc. Customize according to customer needs.

Scraper type self-cleaning rotary valve/discharge valve, comprising a motor and a housing, characterized by an arc-shaped impeller and a rotating scraper. The arc-shaped impeller is installed inside the housing and is driven by a motor; The rotating scraper is set below the arc-shaped impeller, and the top of the scraper discharge valve rotating scraper is in contact with the arc-shaped surface of the impeller. The rotating scraper of the discharge valve and the arc-shaped impeller rotate synchronously and in reverse through a gear transmission mechanism outside the housing.

Construction case

Related products