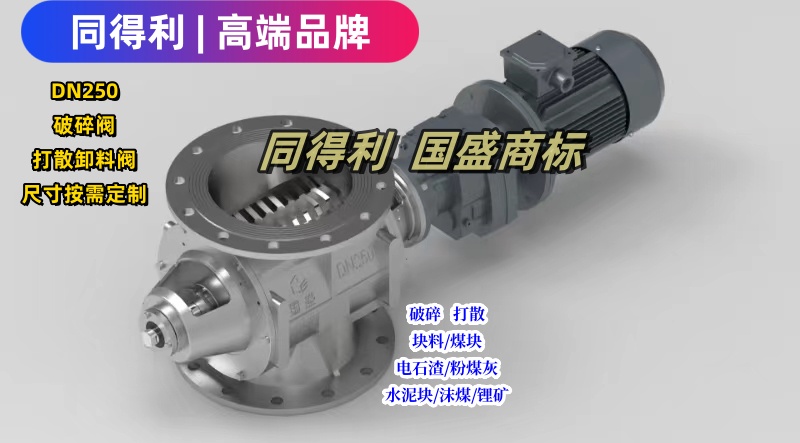

【破碎<10mm】旋转破碎阀-破碎卸料阀

【破碎<10mm】旋转破碎阀-破碎卸料阀

| 参数名称 | 参数值 |

|---|---|

| 品名 | 破碎阀,破碎打散卸料阀,打散破碎阀,打散卸料阀,旋转破碎阀,破碎卸料阀,破碎旋转阀,破碎卸料器 |

| 破碎物料 | 块料、煤块、电石渣、粉煤灰、水泥块、沫煤、锂矿、结块物料、磷酸铁粉、碳酸钙、炭黑结块 |

| 破碎程度 | <10mm;6mm~12mm;定制 |

| 常规尺寸 | DN50,DN100,DN150,DN200,DN250,DN300,DN350,DN400,DN450,DN500,或方口,或非标定做 |

| 卸料量 | 0.1t/h ~ 1200t/h;或非标定制尺寸 |

| 破碎阀特点 | 轻松破碎,密封锁气,定量卸料或变频,按客户需求 |

| 品牌 | 常州同得利,江苏同得利,国盛商标,对标全球一线品牌 |

| 联系电话(陈经理) | 18068546632 |

The main function of the rotary crushing valve is to crush the block materials in the material flow of the unloader. These block materials are formed by moisture in the warehouse or bin. When large blocks of material appear in the material, they can be immediately crushed to prevent them from blocking the channel of the unloading valve and improve smooth unloading. The rotor of the crushing valve is equipped with radially arranged crushing claws, which move the block materials through the grid and crush them.

The operational safety of the block material crushing valve unloader is ensured by the motor speed detection device integrated in the electric control box. When some block materials in the material cannot be crushed and get stuck in the rotor, the speed detection device will alarm and automatically reverse, pushing away the block materials that cannot be crushed before proceeding with forward rotation. When both forward and reverse rotation are stuck, the crushing valve will automatically stop and wait for the fault to be resolved before running again. The speed detection device is an optional device, and this requirement needs to be explained when ordering the equipment.

旋转破碎阀主要功能是破碎卸料器物料流中的块料,这些块料是物料在库内或仓中因受潮而形成,当物料中出现较大块状物时,可立即将其破碎,以防止这些大块物料堵塞卸料阀门的通道,提高通畅卸料,破碎阀的转子上安装有放射状布置的破碎爪,拨动块料物料通过栅格并将其破碎。

块料破碎阀卸料器的运转安全性是通过在电控箱中集成的电机转速检测装置来保证,当物料中的某些块料物料无法破碎而卡住转子时,转速检测装置将报警并自动反转,将无法破碎块料物料推开后再进行正转。当正转或反转都被卡住时,破碎阀则自动停机,等待排除故障后再运行。转速检测装置为选配装置,有此要求时需要在设备订货时说明。【电话/微信咨询:陈经理18068546632】

常见破碎物料:沫煤、锂矿、结块颗粒、磷酸铁粉、电石渣烧生石灰、碳酸钙、锂电池正极材料碳纳米管材料、硬脂酸盐产品、净化灰块状物料、炭黑结块。

旋转破碎阀设计特点:

蕞大型号的通过量可达1200m3/h,或非标定做。

适用于各种气化斜槽和储库卸料出口。

为高达350度的物料温度而设计,更高温度可配水冷式定做。

低能耗,维护简单。

破碎爪和栅格板使用高耐磨材料。

集成转速检测装置(选配项)。

破碎后块料常规直径<10mm,更精细可定做。

密封锁气,可配气密封装置,高精度密封锁气。破碎阀非标尺寸可定制。

部分客户需求:

1、破碎阀DN500. PN6.介质:锂辉石酸化熟料,破碎前≤30mm,破碎到≤10mm;含水率≤6%,物料堆密度890g/m³;介质流量37t/h;工作温度300℃。

2、物料:氧化铝粉末可能结块,需要打散一下,从烘干设备出来可能会成团-破碎阀。导热粉体材料(球形氧化铝、类球形氧化铝、氮化铝、氮化硼)、电磁屏蔽粉体材料(镍包石墨),以及锂电极片涂覆及隔膜涂层材料等。

3、化工物料:三氯化锂,需要破碎,高密封不能进空气,耐腐蚀,破碎至小于30mm,以前用过德国进口科倍隆的。高纯盐酸(HCl)次氯酸钠(NaClO)合成盐酸(HCl)食品级盐酸,液氯(Cl₂)高品质氢氧化钾。

4、物料:锂电池正极材料碳纳米管,料很轻粉末,现在卸料有问题,粉末飞起来不好卸料,想把料凝固成颗粒类的然后破碎卸料。

5、物料:硬脂酸盐产品,物料有些像爆米花的形状,轻抛体积大,想破碎增大物料的堆密度,物料大小一般10-20cm,要求下料速度快,破碎越小越好,下料管道DN300.物料温度高的时候会有一点粘。

6、旋转破碎阀:DN200.PN=1.0MPa,容积:6L处理物料:净化灰(块状物料占比约5%),配防爆电机:功率:1.5KW,防爆等级ExdIICT4减速机:SAF硬齿面减速机,转速:180r/min,处理里:0.4m³/min,破碎后粒度:2-5片状,壳体材质:WCB,厚度:14mm,端盖:WCB,厚度:16mm,转子叶片:材质不锈钢,厚度8mm,叶片间隙:2-5mm,转轴材质:不锈钢,带配对法兰及紧固件。

7、物料:沫煤,要求:破碎+密封。

8、西草甲型结块,吨包物料打散进仓电动破碎阀。

9、物料:粉体材料,小结块颗粒可粉料,需要卸料破碎器。

10、物料:石灰粉,300*300.碳钢材质。【电话/微信咨询:陈经理18068546632】

11、DN300破碎阀,转数328r/min 破碎≤10mm,减速机泰隆RF47-3KW,电机不防爆品牌皖南,与物料接触部分材质304.含铜量≤0.5%,输送介质无水磷酸铁粉体材料,物料温度200℃,PH值1.8-2.5;破碎动刀淬火处理,齿厚8mm间隙10mm,破碎阀内部要求无毛刺锐边,清洁干净无残存金属和其他粉末,进出料口封闭。

12、破碎阀,破碎物料Ca0、结块料、部分浇注料,物料温度200℃,进料粒度:>50mm 的料预计10%,个别结块料可达 80mm,出料粒度<8mm,处理量45t/h,Ca0 堆积密度0.7t/m³。

13、高温电动破碎阀,块状物料水泥半成品,规格500*800.温度600℃,密封功能要好。

14、化工物料:不到15mm化工产品有腐蚀性,料仓下料易结块堵塞,严重影响称重计量包装,需要加装一台破碎卸料阀,DN300接口,316L材质。

15、物料:炭黑,结块4-5cm,旋转破碎阀不锈钢,尺寸DN300.【电话/微信咨询:陈经理18068546632】

16、物料石块,破碎卸料器1:每小时2吨左右 温度:150℃。2:大料尺寸100mm,需要处理到10mm以下。3:大颗粒量约为每小时1吨。4:现场高度500mm上下一样的法兰接口,阀体材质:316L*10mm,动静齿材质:316L*6mm,法兰材质:316L*12mm,主轴材质:316L*55mm,间隙面积:约为总面积的10%。电机11KW减速比 i=19.25减速机:硬齿面K87系列(变频防爆)。

17、旋转破碎阀,物料:盐,硝酸钠在干燥过程中,有结块,影响下游螺旋输送机。

18、物料:抗氧剂块料,有点结块,挺硬的。需要破碎阀,DN500.

19、破碎阀DN500. PN6.介质:锂辉石酸化熟料,破碎前≤30mm;含水率≤6%,物料堆密度890g/m³;介质流量35t/h;工作温度300℃。

20、炉子出来的可能存在块状盐,500-600度,需要打散,同时卸料阀要降温措施保护电机,破碎尺寸5CM以内。【电话/微信咨询:陈经理18068546632】

《扫二维码-添加 陈经理微信 咨询破碎打散卸料阀》

Common crushed materials: foam coal, lithium ore, agglomerated particles, iron phosphate powder, calcined quicklime from carbide slag, calcium carbonate, positive electrode material for lithium batteries, carbon nanotube material, stearate products, purified ash block materials, carbon black agglomerates.

Partial customer requirements:

Crushing valve DN500. PN6. Medium: spodumene acid clinker, ≤ 30mm before crushing, ≤ 10mm after crushing; Moisture content ≤ 6%, material bulk density 890g/m ³; Medium flow rate 37t/h; The working temperature is 300 ℃.

Material: Aluminum oxide powder may clump and need to be broken up, and it may form clumps when coming out of the drying equipment - crushing valve. Thermal conductive powder materials (spherical alumina, quasi spherical alumina, aluminum nitride, boron nitride), electromagnetic shielding powder materials (nickel coated graphite), as well as lithium electrode sheet coating and diaphragm coating materials.

Chemical material: Lithium trichloride, needs to be crushed, highly sealed and cannot enter air, corrosion-resistant, crushed to less than 30mm, previously used from Germany imported Kobelon. High purity hydrochloric acid (HCl) and sodium hypochlorite (NaClO) are used to synthesize food grade hydrochloric acid (HCl) and high-quality potassium hydroxide for liquid chlorine (Cl ₂).

Material: Carbon nanotubes, the positive electrode material of lithium batteries, are a very light powder. There is a problem with unloading now, as the powder flies and is difficult to unload. I want to solidify the material into particles and then crush them for unloading.

Material: stearic acid salt product. The material has a shape similar to popcorn and has a large volume when lightly thrown. If you want to increase the bulk density of the material by crushing it, the material size is generally 10-20cm. The material needs to be cut quickly and the smaller the crushing, the better. The cutting pipeline is DN300. and the material will be a little sticky when the temperature is high.

Construction case

Related products