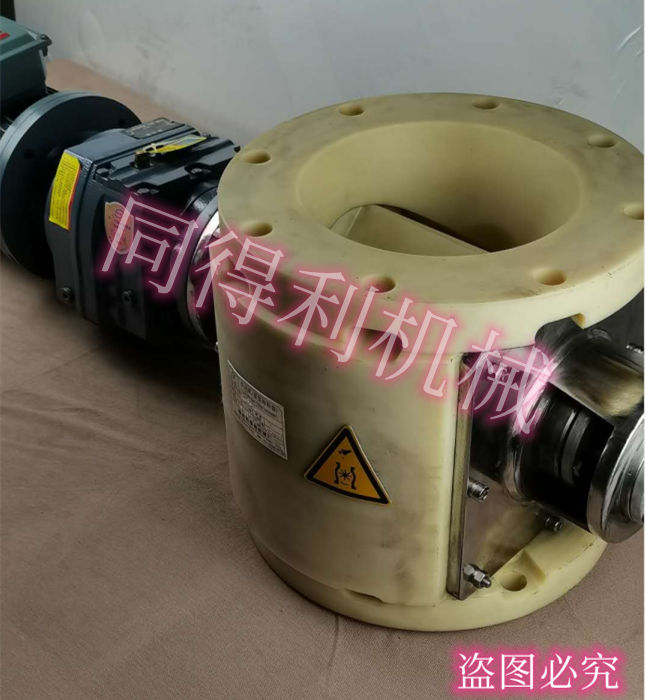

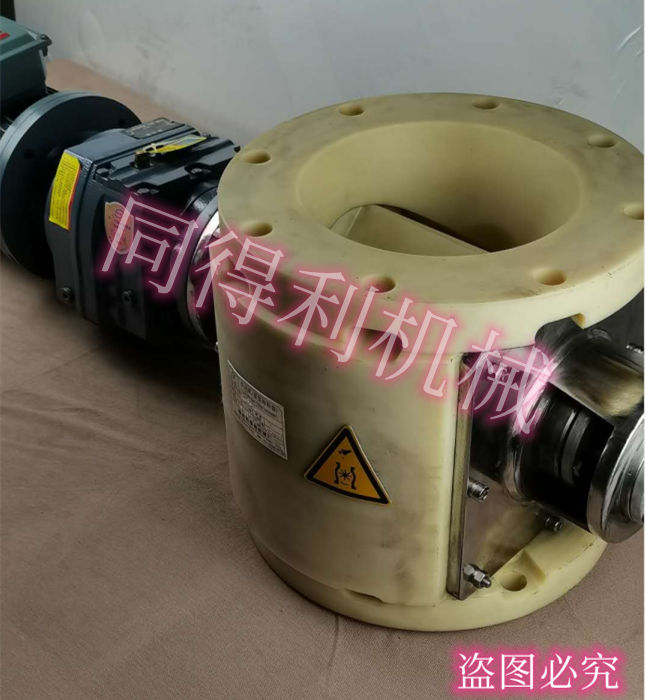

整体尼龙旋转供料器

整体尼龙旋转供料器

| 参数名称 | 参数值 |

|---|---|

| 品名 | 尼龙旋转供料器,尼龙旋转阀 |

| 材质 | 改性尼龙 |

| 主要结构 | 壳体、叶轮、端盖 |

| 输送物料(介质) | 电池正极材料、磷酸铁锂、三元材料 |

| 特点 | 耐磨、耐高温 |

旋转供料器(又称电动锁气器、旋转阀、星形下料器)广泛地应用于中低压气力输送系统中,它有定量供料与锁气的功能。它利用压缩空气或罗茨鼓风机作为气源将物料从一个点输送到另一个点的技术,具有可以将由数点集中的物料送往一处或有一处送往分散的数点,并实现输送等特点,具有粉体输送等作用,常用于化工、锻造、半导体、玻纤等行业。旋转供料器主要由主阀(壳体,端盖,叶轮,密封结构等),电机减速机,防护装置(链轮,链轮罩等),排气口等组成。

本卸料装置是除尘设备排灰、送风和其它设备给料的主要设备,适用于粉状物料和颗粒状物料。

尼龙旋转供料器采用加厚叶轮设计,与壳体配合间隙小,结构精密,使用过程中不易漏风不易漏料,防堵耐用。

密封优越,用感无忧:结构稳定,密封性能良好。可用于粉料、小颗粒物料,在正负极压差吸送过程中将物料分离排出。

此产品由本公司自主研制,适用于不可接触金属物料的卸料。箱体、叶轮以及端盖,都采用整块尼龙铣削加工,结构牢靠,运行无噪音,相较于陶瓷阀,可以节省成本,是锂电行业新宠。

Rotating feeders (also known as electric air locks, rotary valves, and star shaped feeders) are widely used in medium and low pressure pneumatic conveying systems, with the function of quantitative feeding and air locking. It uses compressed air or Roots blower as a gas source to transport materials from one point to another. It has the characteristics of being able to transport materials concentrated by points to one or scattered points, and achieve conveying. It has the function of powder conveying and is commonly used in industries such as chemical, forging, semiconductor, fiberglass, etc. The rotary feeder mainly consists of the main valve (shell, end cover, impeller, sealing structure, etc.), motor reducer, protective device (sprocket, sprocket cover, etc.), exhaust port, etc.

This discharge device is the main equipment for dust removal equipment, ash discharge, air supply, and other equipment feeding, suitable for powdered and granular materials.

The nylon rotary feeder adopts a thickened impeller design, with small clearance with the shell, precise structure, and is not prone to air leakage or material leakage during use, making it resistant to blockage and durable.

Superior sealing and worry free use: stable structure and good sealing performance. Can be used for powder and small particle materials, to separate and discharge materials during the positive and negative pressure difference suction process.

This product is independently developed by our company and is suitable for unloading non-contact metal materials. The casing, impeller, and end cover are all processed using a single piece of nylon milling, with a reliable structure and noiseless operation. Compared to ceramic valves, they can save costs and are a new favorite in the lithium battery industry.

Construction case

Related products