我们只做高品质的产品

公司以诚信、实力和产品质量获得业界的认可,欢迎各界朋友莅临参观,指导和业务洽谈

-

尼龙快拆卸料阀/ 尼龙卸料器,快拆清洗卸料阀,自清洁卸料阀

产品介绍卸料阀可分为:普通型,耐压型,外装耐温耐压型,快速清洗型,定量型。 尼龙快拆卸料阀由本公司自主研制,适用于不可接触金属物料的卸料。箱体、叶轮以及端盖,都采用整块尼龙铣削加工,结构牢靠,运行无噪音,相较于陶瓷阀,可以节省成本,是锂电行业新宠。【电话/微信咨询:陈经理18068546632】 锂电池正负极原料输送旋转卸料阀常见分类有:滑杆星型卸料阀,侧快拆卸料阀,陶瓷星型卸料阀,尼龙旋转卸料阀,钛合金星型卸料阀,四氟星型卸料阀,耐压星型卸料阀。 尼龙快拆卸料阀主要结构:壳体、叶轮、端盖,采用改性尼龙。 主要用于输送电池正极材料、磷酸铁锂、三元材料等。 特点:改性尼龙比普通尼龙更耐磨,耐高温。【电话/微信咨询:陈经理18068546632】 常州同得利技术研发于2016年,批量生产于2018年,2020年更新第4代尼龙星型阀,目前有尼龙星型阀发明专 利。 《扫二维码-添加 陈经理 微信-咨询产品或定制》 The discharge valve can be divided into: ordinary type, pressure resistant type, external temperature and pressure resistant type, quick cleaning type, and quantitative type. The nylon quick disassembly material valve is independently developed by our company and is suitable for unloading non-contact metal materials. The casing, impeller, and end cover are all processed using a single piece of nylon milling, with a reliable structure and noiseless operation. Compared to ceramic valves, they can save costs and are a new favorite in the lithium battery industry. The common classifications of rotary discharge valves for the transportation of positive and negative raw materials in lithium batteries include: sliding rod star discharge valves, side quick release valves, ceramic star discharge valves, nylon rotary discharge valves, titanium alloy star discharge valves, PTFE star discharge valves, and pressure resistant star discharge valves. The main structure of the nylon quick disassembly material valve is a shell, impeller, and end cover, which are made of modified nylon. Mainly used for transporting battery cathode materials, lithium iron phosphate, ternary materials, etc. Features: Modified nylon is more wear-resistant and heat-resistant than ordinary nylon. Changzhou Tongdeli Technology was developed in 2016. mass-produced in 2018. and updated its fourth generation nylon star valve in 2020. Currently, it has a nylon star valve invention patent.查看详情 +

-

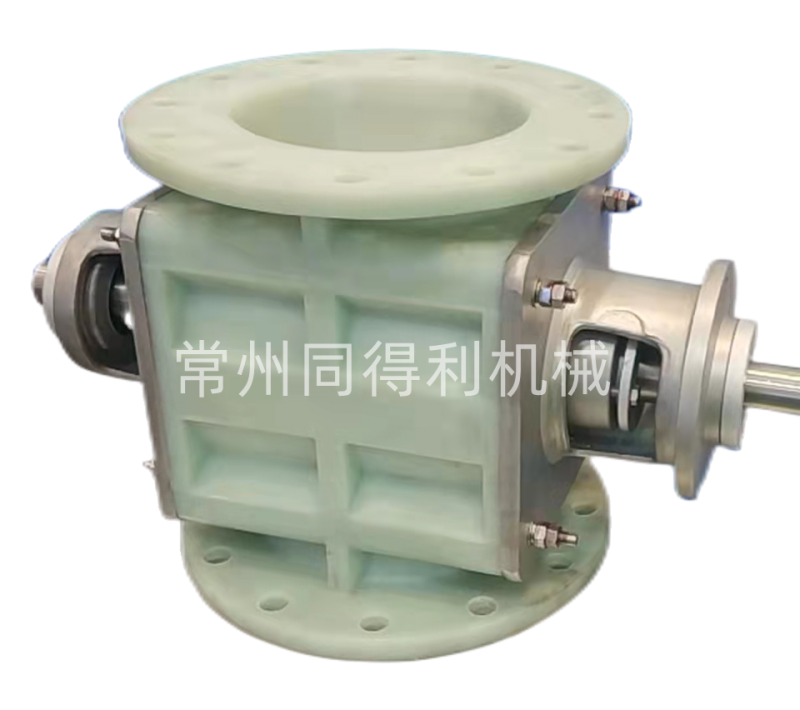

尼龙快拆式旋转阀/ 快拆清洗旋转阀,自清理旋转阀,尼龙旋转阀

产品介绍尼龙快拆式旋转阀密封优越,用感无忧:结构稳定,密封性能良好。可用于粉料、小颗粒物料,在正负极压差吸送过程中将物料分离排出。采用加厚叶轮设计,与壳体配合间隙小,结构精密,使用过程中不易漏风不易漏料,防堵耐用。 此产品由本公司自主研制,适用于不可接触金属物料的卸料。箱体、叶轮以及端盖,都采用整块尼龙铣削加工,结构牢靠,运行无噪音,相较于陶瓷阀,可以节省成本,是锂电行业新宠。【电话/微信咨询:陈经理18068546632】 快速清洗型:快速清洗旋转阀制作精致、成功使用德、日技术制造之精华。产品拆装灵活、易于清洗。主要用于化工、制药、食品等行业高卫生标准的物料卸料及经常更换物料的场所工作。 可拆卸叶轮:便于快速拆卸清洗旋转阀的物料接触面。 驱动方式:链驱动/马达直连驱动。 动力配置:摆线针轮减速机,Y系列电机(可按客户指定动力配置)。 材质:尼龙系列。 滑杆式:清洗前的拆卸。松开螺栓手柄,沿导柱将端盖轻轻拉至极限,抽出叶轮,双手握住叶轮两端抽颈取出。清洗后,装入叶轮(转动叶轮使花键齿合),推入端盖(转动活动轴柄使花键齿合),拧紧螺栓手柄。【电话/微信咨询:陈经理18068546632】 快开门式:操作方法基本如上所述。 《扫二维码-添加 陈经理 微信-咨询产品或定制》 Nylon quick release rotary valve has superior sealing and worry free use: stable structure and good sealing performance. Can be used for powder and small particle materials, to separate and discharge materials during the positive and negative pressure difference suction process. Adopting a thickened impeller design, the clearance between the impeller and the shell is small, the structure is precise, and it is not easy to leak air or materials during use, and it is durable and anti clogging. This product is independently developed by our company and is suitable for unloading non-contact metal materials. The casing, impeller, and end cover are all processed using a single piece of nylon milling, with a reliable structure and noiseless operation. Compared to ceramic valves, they can save costs and are a new favorite in the lithium battery industry. Rapid cleaning type: the rapid cleaning rotary valve is exquisitely made, and successfully uses the essence of German and Japanese technology. The product is flexible in disassembly and easy to clean. Mainly used for unloading materials with high hygiene standards in industries such as chemical, pharmaceutical, and food, as well as working in places where materials are frequently replaced. Detachable impeller: facilitates quick disassembly and cleaning of the material contact surface of the rotary valve. Drive mode: chain drive/motor direct connection drive. Power configuration: cycloidal pinwheel reducer, Y-series motor (can be configured according to customer specifications). Material: Nylon series. Sliding rod type: disassembly before cleaning. Release the bolt handle, gently pull the end cover along the guide pillar to the limit, extract the impeller, and hold both ends of the impeller with both hands to extract the necks. After cleaning, install the impeller (rotate the impeller to fit the spline teeth), push in the end cover (rotate the movable shaft handle to fit the spline teeth), and tighten the bolt handle. Quick opening type: The operation method is basically as described above.查看详情 +

-

尼龙旋转卸料器/ 尼龙卸料阀,尼龙旋转阀,尼龙旋转卸料器

产品介绍尼龙旋转卸料器主要结构:壳体、叶轮、端盖,采用改性尼龙。 主要用于输送电池正极材料、磷酸铁锂、三元材料等。 特点:改性尼龙比普通尼龙更耐磨,耐高温。 常州同得利技术研发于2016年,批量生产于2018年,2020年更新第4代尼龙星型阀,目前有尼龙星型阀发明专 利。【电话/微信咨询:陈经理18068546632】 我公司专 业生产(B)GFY、YJD系列关风机(关风器)、星型卸料器、DS系列电动锁气器、DN型旋转阀,快开阀、清洁阀、风送式旋转阀等产品。广泛应用于粮食、饲料、石油化工、制药、淀粉、油脂、化工干燥、除尘、冶金、环保、电子、煤炭、建筑、电力机械等行业设备上。用于固体粒料、粉料、超微粉体在气力输送及管网正负压状态下的卸料。 《扫二维码-添加 陈经理 微信-咨询产品或定制》 The main structure of the nylon rotary unloader is a shell, impeller, and end cover, made of modified nylon. Mainly used for transporting battery cathode materials, lithium iron phosphate, ternary materials, etc. Features: Modified nylon is more wear-resistant and heat-resistant than ordinary nylon. Changzhou Tongdeli Technology was developed in 2016. mass-produced in 2018. and updated its fourth generation nylon star valve in 2020. Currently, it has a nylon star valve invention patent. Our company specializes in the production of (B) GFY, YJD series shut-off fans (shut-off fans), star shaped unloaders, DS series electric air locks, DN type rotary valves, quick opening valves, cleaning valves, pneumatic rotary valves, and other products. Widely used in industries such as grain, feed, petrochemicals, pharmaceuticals, starch, fats, chemical drying, dust removal, metallurgy, environmental protection, electronics, coal, construction, and power machinery. Used for unloading solid particles, powders, and ultrafine powders under pneumatic conveying and positive and negative pressure in pipeline networks.查看详情 +

-

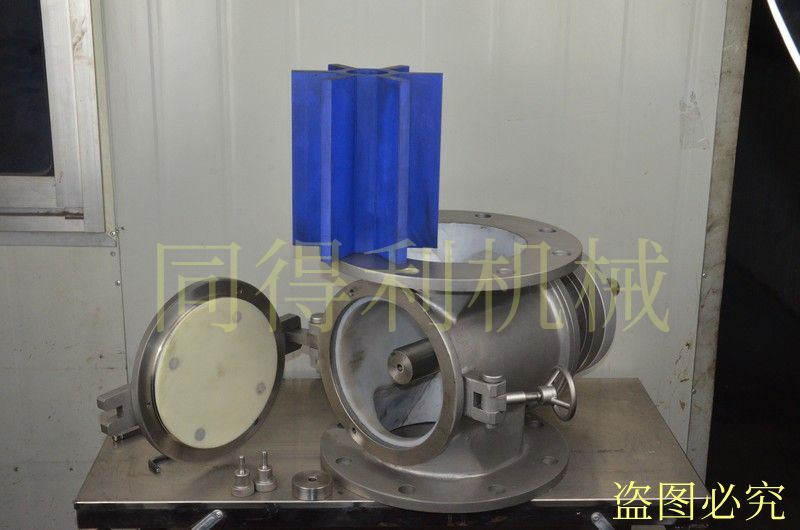

滑杆式陶瓷旋转阀/ 滑杆式旋转阀,陶瓷旋转阀,旋转阀,快拆式旋转阀

产品介绍本产品由本公司自主研制,已取得多项国家专 利。本品适用于不可接触金属物料,多用于锂电正极原料的生产制作。陶瓷阀的优点是超强耐磨,而且不会对锂电材料造成污染,是新能源大开发进程中一大助力。 主要结构:外壳金属。 物料接触部分:内衬陶瓷(也可尼龙、四氟等)。 适用范围:用于输送电池正极材料、磷酸铁锂、三元材料等。食品药材原料输送。 特点:针对物料粘接,快拆清理,快速复位。 主要材料:不锈钢304-316、陶瓷氧化铝。【电话/微信咨询:陈经理18068546632】This product is independently developed by our company and has obtained multiple national patents. This product is suitable for non-contact metal materials and is mainly used in the production and production of lithium battery cathode materials. The advantage of ceramic valves is that they are super wear-resistant and do not cause pollution to lithium-ion materials, making them a major contributor to the development of new energy.Main structure: Metal shell.Material contact part: lined with ceramic (nylon, PTFE, etc.).Scope of application: Used for transporting battery cathode materials, lithium iron phosphate, ternary materials, etc. Transportation of food and medicinal materials.Features: For material bonding, quick disassembly and cleaning, quick reset.Main materials: stainless steel 304 316, ceramic alumina.查看详情 +

-

关风机/

-

关风机/

-

【国产 VS 进口】螺旋输送机&喂料机/ 管式螺旋输送机,绞龙输送机,螺旋输送机,螺旋喂料机,螺杆上料机

产品介绍螺旋输送机又称为倾斜螺旋输送机、管式螺旋输送机、移动螺旋输送机、绞龙输送机或蛟龙输送机。 螺旋输送机适应工况: 主要用于输送颗粒状、粉状和小块物料,不适用于输送黏性大,易结块,易变质的物料,因为这些物料在输送时会粘结在螺旋叶片上,并随着旋转而不向前移动,或者在吊轴处形成物料的堵塞,而使螺旋输送机不能正常工作。 螺旋输送机的工作原理: 螺旋输送机的工作原理是利用物料的重力及其与槽体壁所产生的摩擦力。物料在中间轴承的运移是依靠后面前进着的物料的推力。所以,物料在输送机中的运送,完全是一种滑移运动。 【槽状螺旋输送机】 《磨粉用槽式螺旋输送机-为磨粉机而设计》 槽式螺旋输送机主要用于面粉研磨行业,尤其是输送谷粒、面粉和糠类副产品。螺旋输送机由碳钢制成,其表面经过食品级别的处理。还配备有齿轮减速箱和电机。可以提供经认证的防爆型号。【电话/微信咨询:陈经理18068546632】 《不锈钢槽式螺旋输送机》 标准 304L 或 316L 不锈钢设计,带有外部可调轴承密封件(填料密封、空气净化或气体净化密封等)的尾部轴承组件。有轻型和中型两种,所有产品均有防爆型号。【电话/微信咨询:陈经理18068546632】 《管型螺旋输送机》 轻载重型主要用于面粉和面粉研磨副产品的进料和输送。中等载重型主要用于动物研磨饲料产品如谷物、粗粉以及研磨副产品的输送。一般而言,管状螺旋输送机和喂料机在应用中能够减少物料残余量和保持物料颗粒原始尺寸。【电话/微信咨询:陈经理 18068546632】 《槽式螺旋输送机》 粉末喷涂,螺旋叶片焊接在中心管上,槽体有标准的法兰连接截面,标准长度。槽状螺旋输送机可为输送粉末或颗粒材料提供多种解决方案。宠物食品、塑料加工、肥皂、洗衣粉和清洁剂加工、动物饲料加工、木材加工、化学品、环境技术、水泥、石灰和石膏加工以及矿业。【电话/微信咨询:陈经理 18068546632】 《动物副产品螺旋输送机》 槽式螺旋输送机由碳钢制成,并且经过合适的表面处理(主要经过热镀处理)。配有满足需求的齿轮减速箱和电机。槽状螺旋输送机采用不间断运行设计,用于输送屠宰业副产品,比如骨头(整块或碾碎)、蹄、头或肥肉。【电话/微信咨询:陈经理 18068546632】 《锥形单轴螺旋喂料机》 锥形单轨螺旋喂料机主要用于面粉加工厂,拥有两个锥形入口螺旋和套管,确保同步卸料和喂料。减少了物料在进料槽的残留。锥形螺旋(方形截面)和槽体由碳钢制成,恒定的喂料速度,坚固设计,高卸料效率。【电话/微信咨询:陈经理 18068546632】 《锥形双轴螺旋喂料机》 双轴螺旋喂料机对于要求极高 效地从料箱或料斗卸料/喂料的用户而言是不错的选择。设计用于装卸非同质材料(木、碎屑、纸等)、面粉加工业材料(糠、面粉等)以及挂料材料(如锯屑、大豆等)。喂料面积大,避免了桥接,避免了偏析,即使是难于处理的物料也能保证持续喂料,可靠恒定的喂料速度,高度自清理,槽体清理方便,可以提供防爆型螺旋喂料机。【电话/微信咨询:陈经理 18068546632】 《高温螺旋输送机》 超重型槽式螺旋输送机或喂料机专为中高温和高温应用设计。高温螺旋输送机由碳钢或不锈钢制成,经过适当的表面处理。可完全满足输送或喂料要求,尤其是铸造厂、钢铁厂,炼钢厂、发电厂(粉煤灰处理)或干燥设备中的再生砂。【电话/微信咨询:陈经理 18068546632】 《新拌混凝土用螺旋输送机》 在混凝土预制行业中,输送机用于将新拌混凝土从浆叶式搅拌机输送到模子中。而以前的皮带输送机则有可能导致混凝土分离。为了保持混凝土均匀和减少驱动力,可以调整进料口部位的混合桨。通过调整桨的角度,可以改变混凝土的生产率。橡胶制槽底板的柔韧性使得螺旋与槽体之间的大块物料不会堵塞在槽体内。当槽底板磨损后,可以快速开合以进行清理和更换。【电话/微信咨询:陈经理 18068546632】 【管状螺旋输送机】 《管式螺旋输送机》 管状螺旋输送机和喂料机系统用途极广,可为输送粉末或颗粒材料提供各种标准的解决方案。可为各项应用提供不同型号的输送机或喂料机,比如混凝土生产(适用粉媒灰、填料粉尘、硅粉)、预混合建筑材料(干石膏、沙、水泥、添加剂)、玻璃加工(碳酸钙、苏打、沙等)、铸造厂(沙、膨润土)等。【电话/微信咨询:陈经理 18068546632】 《不锈钢管式螺旋输送机》 标准304L或316L不锈钢设计,不锈钢管状螺旋输送机为输送或喂入粉末或颗粒材料提供各种解决方案。对使用环境的要求:环境对物料无任何污染、绝 对清洁、绝 对防腐蚀。管状螺旋输送机尤其适用于环境技术、面粉和动物饲料加工、食品加工和包装、塑料和化学品以及医药行业。【电话/微信咨询:陈经理 18068546632】 《食品级不锈钢管式螺旋输送机》 不锈钢管式螺旋输送机是食品行业前沿的解决方案。确保设备的组件表面平滑,这就是物料残留极小的原因。适用于需物料不受任何污染和要求绝 对清洁以及耐腐蚀的应用。标准304L或316L不锈钢设计,易于维护,从管状输送机中取出螺旋方便。【电话/微信咨询:陈经理 18068546632】 《超低物料残留管式螺旋输送机》 内部无螺钉螺栓,方便输送机零件清理,同时降低了物料残留。残留在更大程度上是由螺旋轴线在外管底部方向的微小偏移所产生的二者之间的间隔引致。螺旋叶片和槽体的间隙不超过5mm。另一方面,螺旋与底板之间的轴向间隙为2.5mm。适合用于散装物料的输送和喂料,主要用于食品行业、塑料和化学制品处理,以及特定限 制范围内的制药行业。表面光滑(内部无螺栓螺母)可以方便、快速地从管式输送机壳中抽出螺旋。【电话/微信咨询:陈经理 18068546632】 《单轴螺旋喂料机》 一些粉末或颗粒材料流动性极差,以致无法用圆形排放孔式的锥体装置将其存储于料仓中,需要用更陡峭的椎体装置及椭圆形排放口将其存储于料仓中。单轴螺旋喂料机与料仓出口的形状相契合。料槽部分与管状部分相连接,可有效喂入材料以便进一步加工。有防爆型号可选。【电话/微信咨询:陈经理 18068546632】 《精确喂料螺旋输送机》 低转速 (SPS),防磨材料制成的螺旋,主螺旋与精确喂料螺旋之间连接料斗,范围宽广,可以用于各种物料,包括高磨损性物料。精确喂料螺旋主要用作输送量大的主螺旋喂料机的补充。在接近设定的喂料量时,用接近开关将主螺旋喂料机关闭,进而用法兰连接在主螺旋出料端下方的精确喂料螺旋进行精确喂料,将物料从主螺旋的出料口输送到重量料斗内。【电话/微信咨询:陈经理 18068546632】 《重载型管式螺旋输送机》 主要用于间歇作业和连续作业情况,产品耐用和易于更换易坏零件。附加的进出料口,附加的观察窗。这类螺旋输送机常见于矿物加工、玻璃加工、铸造厂、水泥厂、石膏和石灰生产等应用以及矿业中。【电话/微信咨询:陈经理 18068546632】 《水泥螺旋喂料机》 主要用于下列物料的喂料和输送:混凝土生产厂的水泥和类似水泥的粉料,也可以用于其它建筑材料的加工过程中。粉末喷涂,外管包括焊接末端法兰、进料口、出料口,观察窗在进料口和中间吊挂轴承的下面。耐用,维护方便,进料口和出料口通用,安装快,高性价比。【电话/微信咨询:陈经理 18068546632】 《容积计量式水泥螺旋喂料机》 专为容积计量喂入水泥或类似材料而设计,产品配备大型入口料斗。压力开关一检测到进口料斗内无物料,ESV螺旋喂料机便会停止工作。【电话/微信咨询:陈经理 18068546632】 《管式带状叶片螺旋喂料机》 带式螺旋叶螺旋喂料机确保在特殊的石灰投加设备中将石灰均匀卸下和喂入溶解设备或微型喂料设备。考虑到实际应用情况,通常配有变速驱动。进料口下设有标准观察窗,进料速度从70到4500升/小时,物料流动平缓,喂料精确度高。【电话/微信咨询:陈经理 18068546632】 《污泥用垂直螺旋输送机》 有效输送不同种类的污泥 当前,淤泥处理技术需要投入越来越多的相关设备设施,例如:搅拌机、污水处理设备等。对这些设备的喂料和卸料需要将淤泥提升到较高位置。保证了恒定的喂料速度和淤泥的进一步混合。考虑到腐蚀或磨损,为确保螺旋输送机耐用,可以选择碳钢或不锈钢材料,无味操作,清洗时间短,高性价比。【电话/微信咨询:陈经理 18068546632】 《垂直螺旋输送机》 垂直螺旋输送机系统包括两部分:一个水平螺旋喂料机,用于从料斗、料仓或其他的喂料机、输送机中接收物料;一个垂直螺旋输送机,将物料提升到一定高度。物料可以被卸载到一个高处料斗、一个或多个箱柜或料仓,或者传递到其他的输送机或输送系统。经过特殊设计的制造件、螺旋和轴承组件使得系统维护方便。【电话/微信咨询:陈经理 18068546632】 《填料粉末螺旋喂料机和输送机》 专为处理沥青厂的填料尘埃 填料粉末螺旋喂料机和输送机专为满足沥青行业的主要要求而设计,用于固定式沥青厂喂入和输送冷热填料粉末。一端连接中 央粉末过滤器,另一端连接混合设备的存储料仓及称重料斗。连接法兰,可调节卡箍式管支架。【电话/微信咨询:陈经理 18068546632】 《无轴螺旋输送机》 输送不容易处理的物料 物料靠无轴的重负载螺旋叶片输送,无轴螺旋叶片在槽体中被放置在特殊材料制成的耐磨衬垫上。可以纵向拆分的U型槽板由碳钢或304L/316L不锈钢制成。用于输送城市固体废料、筛渣和漂浮物、脱水淤渣、稠化淤渣或调和淤渣、包装食品、乳脂或膏以及肉类、鱼类、果蔬加工废料。应用的主要领域:一般用于废水处理、制糖厂废料、鱼类工业、固体废料处理、果蔬加工厂、饮料工业、造纸业、化工、食品业、肉类加工厂、屠宰场、餐馆、食堂和餐饮等。【电话/微信咨询:陈经理 18068546632】 《扫二维码-添加 陈经理 微信-咨询螺旋输送机》查看详情 +

-

防卡型关风机-链驱动/ 关风器卸料阀,防卡旋转阀,防卡卸料阀,星型卸料器,关风机

产品介绍关风机/关风器卸料阀入口/出口:入口为圆口并配有透明视窗,以便观察物料的流动状况;出口为方形增大了出口面积使物料顺利排出。 防卡型关风机主要用于塑料、化工、食品、制药、木材原料输送。 针对颗粒、片状、块状物料,实现不卡料、不堵料。【电话/微信咨询:陈经理18068546632】 普通型:结构紧凑,占用空间小。 轴承外置式:防止粉尘侵入轴承、增大适应温度的范围。 轴承外置式安装、性能优异。 驱动方式:链驱动/马达直连驱动口。 材质:碳钢、铸铁、不锈钢、陶瓷、尼龙、四氟、特氟龙、钛合金、铝合金、各种合金系列等。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询防卡型关风机》 Shutter/Shutter discharge valve inlet/outlet: The inlet is circular and equipped with a transparent window for observing the flow of materials; The square shape of the outlet increases the outlet area and facilitates the smooth discharge of materials. Anti jamming type air blowers are mainly used for conveying plastic, chemical, food, pharmaceutical, and wood raw materials. For granular, flake, and block materials, achieve no material jamming or blockage.查看详情 +

-

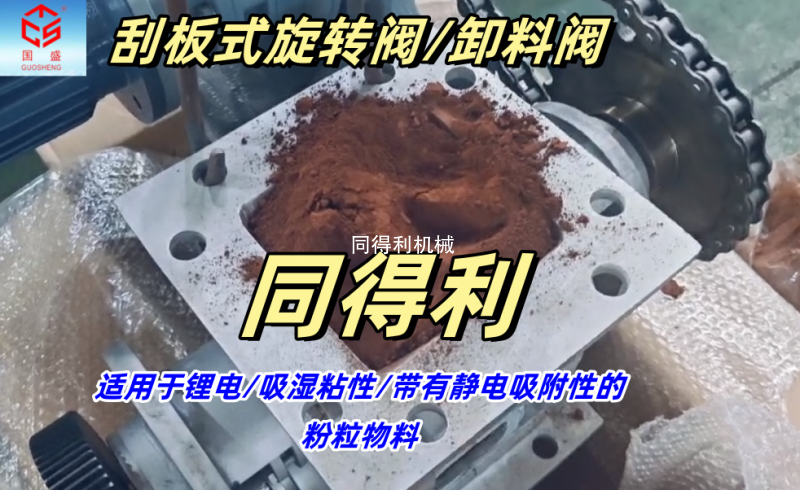

【吸湿性物料】刮板卸料阀-钢厂/电厂/水泥/矿山/ 粘性物料卸料阀,刮板旋转阀,刮板卸料阀,刮板卸料器,钢厂卸料阀

产品介绍(BGB)刮板式卸料阀/旋转阀/星型卸料器系列适用于具有吸湿粘性和带有静电吸附性的粉粒物料。 刮板卸料阀的阀体下部的旋转刮板自动将附在转子料斗内的物料挂落。 阀体上开有清理口,便于定期清除旋转阀内部的物料。 提供链驱动、马达直连驱动。 刮板卸料阀材质:碳钢、不锈钢系列等。【电话/微信咨询:陈经理18068546632】 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询刮板式卸料阀》 The (BGB) scraper type discharge valve/rotary valve/star shaped unloader series is suitable for powder materials with hygroscopic viscosity and electrostatic adsorption. The rotating scraper at the lower part of the valve body of the scraper discharge valve automatically hangs the material attached to the rotor hopper. There is a cleaning port on the valve body for regular removal of materials inside the rotary valve. Provide chain drive and motor direct drive. Material of scraper discharge valve: carbon steel, stainless steel series, etc.查看详情 +

-

侧快拆卸料阀-物料粘接-清洗型卸料阀/ 侧快拆旋转阀,侧快拆卸料阀,快拆星型卸料器,清洁型旋转阀

产品介绍侧快拆卸料阀/旋转阀/星型卸料器主要用于食品、药材、化工、锂电原料输送。 针对物料粘接,快拆清理,快速复位,可把叶轮异地清理。 侧快拆卸料阀主要材质:不锈钢304-316、四氟、尼龙、陶瓷、特氟龙等。 可拆卸叶轮:便于快速拆卸清洗旋转卸料阀的物料接触面。 驱动方式:链驱动/马达直连驱动。 动力配置:摆线针轮减速机,Y系列电机(可按客户指定动力配置)【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询侧快拆卸料阀》 The side quick disassembly valve/rotary valve/star shaped unloader is mainly used for conveying food, medicinal materials, chemicals, and lithium battery raw materials. For material bonding, quick disassembly and cleaning, quick reset, can clean the impeller in a different location. The main materials of the side quick disassembly material valve are stainless steel 304-316. PTFE, nylon, ceramic, PTFE, etc. Detachable impeller: facilitates quick disassembly and cleaning of the material contact surface of the rotary discharge valve. Drive mode: chain drive/direct motor drive. Power configuration: Cycloid pinwheel reducer, Y series motor (can be configured according to customer's specified power)查看详情 +