我们只做高品质的产品

公司以诚信、实力和产品质量获得业界的认可,欢迎各界朋友莅临参观,指导和业务洽谈

-

偏置系列/

-

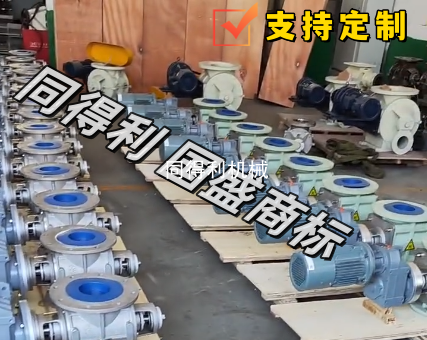

高密封锁气阀/电动锁气器/ 旋转阀,卸料阀,锁气阀,电动锁气器,关风机

产品介绍锁气阀/电动锁气器是气力输送系统中的关键设备,也是除尘和加料系统的常用设备。根据物料的特性、用途和使用条件的不同,电动锁气器有多种结构形式。电动锁气器的选型要依据被输送物料的特性如粒度大小、黏附性、温度、湿度来决定的。【电话/微信咨询:陈经理18068546632】 锁气阀/电动锁气器用途: 电动锁气器适用于火力发电厂粉煤灰、煤粉、石膏粉等物料中近距离(300米内)气力输送系统。也可用于水泥、冶金、化工等其他行业中粉状物料的低压气力输送系统。 常州同得利机械厂主要制造适用于粘性的,含坚硬杂质的以及高温高压或高真空情况下使用的电动锁气器。以及小尺寸的电动锁气器,都是非常规结构非标定制。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询锁气阀/电动锁气器》 Lock valve/electric lock valve is a key equipment in pneumatic conveying system and a commonly used equipment in dust removal and feeding system. According to the characteristics, uses, and usage conditions of materials, electric air locks have various structural forms. The selection of electric air locks should be based on the characteristics of the conveyed material, such as particle size, adhesion, temperature, and humidity. Application of air lock valve/electric air lock: Electric air locks are suitable for close range (within 300 meters) pneumatic conveying systems for materials such as fly ash, coal powder, gypsum powder, etc. in thermal power plants. It can also be used in low-pressure pneumatic conveying systems for powdered materials in other industries such as cement, metallurgy, and chemical engineering. Changzhou Tongdeli Machinery Factory mainly manufactures electric air locks suitable for use in viscous, hard impurity containing, high-temperature, high-pressure, or high vacuum situations. And small-sized electric air locks are all customized with unconventional structures and non-standard specifications.查看详情 +

-

不锈钢气力输送旋转阀-粉料/颗粒/ 不锈钢旋转阀,不锈钢卸料阀,不锈钢星型卸料器,关风机,锁气阀

产品介绍风送式旋转阀/卸料阀压力范围:2kg/cm²系统压力或压差。 增大入口/出口:正方形,没有截面尺寸对料流的限 制从而可达高产量。 轴承外置式:有效的防止粉尘侵入轴承,增大设备适应较高温度的使用范围。 驱动方式:链驱动/马达直连驱动口。 正压稀相气力输送系统是采用罗茨风机或者罗茨空压泵作为动力源。利用空气动能作为输送介质,物料以比较高的速度并以分散悬浮的状态在管道中输送。输送的压力一般根据工况条件不同可在几千帕到几百千帕范围内调整。 正压密相输送系统采用压缩空气作动力源传输物料。采用强制性气力输送,依靠密闭压力容器(发送罐)作发送器,一般气源压力为0.5 Mpa~0.7Mpa,运行压力0.3~0.5Mpa,发送罐只能采取间隙性输送方式,输送路程可达1000m以上。物料在管道内以较低速度、沙丘状态、流态化或团聚状态输送的方式称为正压密相输送。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询不锈钢气力输送旋转阀》 Pressure range of pneumatic rotary valve/discharge valve: 2kg/cm ² system pressure or pressure difference. Increase inlet/outlet: Square, without cross-sectional size restrictions on material flow, thus achieving high yield. External bearing: effectively prevents dust from entering the bearing and increases the equipment's adaptability to higher temperatures. Drive mode: chain drive/motor directly connected to the drive port.查看详情 +

-

【链驱动】偏置式旋转阀-发电厂/钢厂/矿山/水泥/ 链驱动旋转阀,链驱动卸料阀,偏置旋转阀,

产品介绍偏置式旋转阀适用于≤2kg/cm²系统压力或压差。 设置排气口(正压输送时选用)将叶轮旋转带出的气体通过排气口送至排气装置,提高填充效率。 防切料入口设计,即便上游充满物料也可安全启动。偏置式进出料口设计:减少了物料的破碎与损坏。 偏置式旋转阀主要用于钢厂、电厂、水泥、矿山原料输送。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询链驱动偏置式旋转阀》 Biased rotary valves are suitable for system pressures or pressure differentials of ≤ 2kg/cm ². Set up an exhaust port (selected for positive pressure conveying) to send the gas carried out by the impeller rotation to the exhaust device through the exhaust port, improving the filling efficiency. Anti cutting material inlet design ensures safe start-up even when the upstream is filled with materials. Offset inlet and outlet design: reduces material breakage and damage. Offset rotary valves are mainly used for conveying raw materials in steel mills, power plants, cement, and mines.查看详情 +

-

DN300电动破碎阀旋转阀/ 破碎阀,旋转破碎阀,打散破碎阀,电动破碎阀,破碎卸料器

产品介绍电动破碎阀:箱体上的顶端设有进料口,箱体的侧壁开设有出料口,箱体中设有主动转子和从动转子,主动转子上和从动转子上均设有转动破碎板,主动转子和从动转子平行设置,在主动转子的左端设有驱动主动转子转动的驱动电机,主动转子的右端设有主动齿轮,从动转子的右端设置有与主动齿轮啮合的从动齿轮,通过设置相对转动的主动转子和从动转子且在主动转子和从动转子上设置破碎板的方式进行碎料。电动破碎阀 水泥块料破碎机 可拆卸破碎阀、物料破碎阀、粉煤灰破碎打散阀、电石渣破碎打散阀 【电话/微信咨询:陈经理18068546632】破碎物料:沫煤、锂矿、结块颗粒、磷酸铁粉、电石渣烧生石灰、碳酸钙、锂电池正极材料碳纳米管材料、硬脂酸盐产品、净化灰块状物料、炭黑结块 《扫二维码-添加 陈经理 微信-咨询电动破碎阀》Electric crushing valve cement block crusher detachable crushing valve, material crushing valve, fly ash crushing and dispersing valve, carbide slag crushing and dispersing valveCrushed materials: foam coal, lithium ore, agglomerated particles, iron phosphate powder, calcined quicklime from carbide slag, calcium carbonate, positive electrode materials for lithium batteries, carbon nanotube materials, stearate products, purified ash block materials, carbon black agglomerates查看详情 +

-

【纳电】DN200陶瓷卸料阀-国盛卸料阀/ 陶瓷旋转阀,国盛卸料阀,DN200卸料阀,旋转卸料阀

产品介绍DN200陶瓷卸料阀-国盛卸料阀类型:滑杆式/侧快拆/耐高压/耐高温/锁风式/风送滑杆式/防卡型卸料阀(总有一款适合您的需求)陶瓷卸料阀主要结构:外壳金属;物料接触部分:内衬陶瓷(也可尼龙、四氟、特氟龙、聚氨酯等)。陶瓷卸料阀主要用于输送锂电池正极材料,负极材料,磷酸铁锂,三元材料等物料的输送和卸料,可以提高生产效率,保证物料的质量的和稳定性,同时满足环保和安全的要求。陶瓷卸料阀特点:耐高温、耐磨、使用寿命长。陶瓷卸料阀技术研发于2015年,批量生产于2017年,2020年更新第3代陶瓷星型旋转阀,目前有陶瓷星型旋转阀专 利。【电话/微信咨询:陈经理18068546632】锂电/化工卸料阀-陶瓷卸料阀由本公司自主研制,已取得多项国家专 利。本品适用于不可接触金属物料,多用于锂电正极原料的生产制作。陶瓷阀的优点是超强耐磨,而且不会对锂电材料造成污染,是新能源大开发进程中一大助力。 《扫二维码-添加 陈经理 微信-咨询陶瓷卸料阀》DN200 Ceramic Unloading Valve - Guosheng Unloading Valve Types: Sliding Rod/Side Quick Release/High Pressure/High Temperature/Lock Air/Air Delivery Sliding Rod/Anti jamming Unloading Valve (There is always one that suits your needs)The main structure of ceramic discharge valve: metal shell; Material contact part: lined with ceramic (also nylon, PTFE, PTFE, polyurethane, etc.).Ceramic discharge valves are mainly used for conveying and discharging materials such as positive electrode materials, negative electrode materials, lithium iron phosphate, ternary materials, etc. of lithium batteries. They can improve production efficiency, ensure the quality and stability of materials, and meet environmental and safety requirements.查看详情 +

-

DN200内衬陶瓷旋转阀-防尘帽-防异物/ 内衬陶瓷卸料阀,陶瓷旋转阀,内衬陶瓷卸料器,旋转卸料阀

产品介绍DN200内衬陶瓷旋转阀-防尘帽-防异物。本产品由本公司自主研制,已取得多项国家专 利。本品适用于不可接触金属物料,多用于锂电正极原料的生产制作。陶瓷阀的优点是超强耐磨,而且不会对锂电材料造成污染,是新能源大开发进程中一大助力。DN200 lined ceramic rotary valve - dust cap - anti foreign object. This product is independently developed by our company and has obtained multiple national patents. This product is suitable for non-contact metal materials and is mainly used in the production and manufacturing of lithium positive electrode materials. The advantages of ceramic valves are super strong wear resistance and no pollution to lithium battery materials, which is a major boost in the process of new energy development.陶瓷旋转阀主要结构:外壳金属;物料接触部分:内衬陶瓷(也可尼龙、四氟、特氟龙等)。内衬陶瓷旋转阀主要用于输送锂电池正极材料、磷酸铁锂、三元材料等。内衬陶瓷旋转阀特点:耐高温、耐磨、使用寿命长。【电话/微信咨询:陈经理18068546632】技术研发于2015年,批量生产于2017年,2020年更新第3代陶瓷星型旋转阀,目前有陶瓷星型旋转阀专 利。 《扫二维码-添加 陈经理 微信-咨询陶瓷星型阀》The main structure of ceramic rotary valve: metal shell; Material contact part: lined with ceramic (also nylon, PTFE, PTFE, etc.).The lined ceramic rotary valve is mainly used for transporting lithium battery cathode materials, lithium iron phosphate, ternary materials, etc.Features of lined ceramic rotary valve: high temperature resistance, wear resistance, and long service life.The technology was developed in 2015. mass-produced in 2017. and the third-generation ceramic star shaped rotary valve was updated in 2020. Currently, there is a patent for ceramic star shaped rotary valve.查看详情 +

-

【锂电旋转阀】耐高温-四氟旋转阀防粘附/ 锂电卸料阀,高温卸料阀,四氟卸料阀,四氟旋转阀

产品介绍旋转阀/卸料阀的工作原理主要涉及电动机驱动减速机,通过联轴器或链轮使旋转阀的转子旋转。在旋转过程中,材料位于旋转叶片的空间内,叶片的旋转将材料带到排出口,材料的自重使其流入输送系统或储藏室。这种工作方式使得卸料阀能够均匀、连续地向输料管供料,保证气力输出管内的气体和固体物质保持稳定,从而确保气力输送系统的正常工作。同时,卸料阀还具有锁气作用,能够隔断卸料阀上下部的气压。【电话/微信咨询:陈经理18068546632】内衬四氟旋转阀基本介绍:四氟是一种化学性稳定、具有优异的耐高温、耐低温和不粘附性的高分子材料,可以在极端的化学环境下使用。四氟内衬是在金属、陶瓷等材料表面制成的一种覆盖层,主要用于防腐、防粘附和减少摩擦。内衬四氟旋转阀作用:耐高温性:四氟旋转阀卸料阀具有出色的耐高温性能,能够在高温环境下保持稳定的工作状态。它适用于化工反应过程中产生的高温介质的控制和调节,确保旋转阀的密封性和流体的稳定输送。【电话/微信咨询:陈经理18068546632】防粘附作用:四氟旋转阀表面具有良好的不粘附性,能够防止设备表面附着物的黏附,避免管道物料:粉体/颗粒料在长期运行过程中出现结垢、石灰积垢等现象,从而提高了设备的效率。 《扫二维码-添加 陈经理 微信-咨询产品》The working principle of a rotary valve/discharge valve mainly involves an electric motor driving a reducer, which rotates the rotor of the rotary valve through a coupling or sprocket. During the rotation process, the material is located in the space of the rotating blades, and the rotation of the blades brings the material to the discharge outlet. The self weight of the material causes it to flow into the conveying system or storage room. This working method enables the discharge valve to uniformly and continuously feed the conveying pipe, ensuring that the gas and solid substances in the pneumatic output pipe remain stable, thereby ensuring the normal operation of the pneumatic conveying system. At the same time, the discharge valve also has a locking effect, which can block the air pressure at the upper and lower parts of the discharge valve. Introduction to PTFE lined rotary valve:Tetrafluoroethylene is a chemically stable polymer material with excellent resistance to high and low temperatures and non adhesiveness, which can be used in extreme chemical environments. PTFE lining is a covering layer made on the surface of metal, ceramic and other materials, mainly used for corrosion prevention, anti adhesion and reducing friction.Function of PTFE lined rotary valve:High temperature resistance: The PTFE rotary valve discharge valve has excellent high temperature resistance and can maintain a stable working state in high temperature environments. It is suitable for controlling and regulating high-temperature media generated in chemical reaction processes, ensuring the sealing of rotary valves and stable fluid transport.Anti adhesion effect: The surface of the PTFE rotary valve has good non adhesion, which can prevent the adhesion of surface attachments and avoid scaling and lime accumulation of pipeline materials such as powder/particle materials during long-term operation, thereby improving the efficiency of the equipment.查看详情 +

-

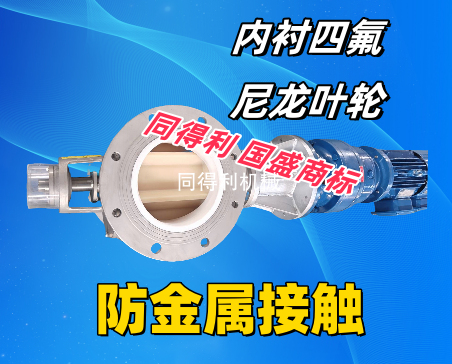

耐高温|内衬四氟-普通尼龙叶轮-锂电旋转阀/ 尼龙旋转阀,高温旋转阀,锂电旋转阀

产品介绍旋转阀(俗称旋转给料器或星型卸料器、星型卸料阀、卸灰阀、星型卸灰阀、锁气阀、关风机、关风机卸料器、关风器、电动锁气器)是应用于粉体(粉沫、颗粒物料、粉粒混合物)输送系统中用来卸料、计量、除尘、定量输送、混合、包装的专用设备。旋转阀广泛用于锂电,化工,环保,石油,冶金,矿山,耐火材料,电力,钢厂,水泥,塑料,粮食医药等行业。四氟是一种化学性稳定、具有优异的耐高温、耐低温和不粘附性的高分子材料,可以在极端的化学环境下使用。内衬四氟是在金属、陶瓷等材料表面制成的一种覆盖层,主要用于防腐、防粘附和减少摩擦。【电话/微信咨询:陈经理18068546632】内衬四氟旋转阀卸料阀是一种特殊设计的阀门,采用四氟材料制造,具有优异的耐腐蚀性和耐高温性能。叶轮尼龙旋转阀适用于不可接触金属物料的卸料。采用整块尼龙铣削加工,结构牢靠,运行无噪音,相较于陶瓷阀,可以节省成本,是锂电行业新宠。尼龙叶轮与壳体配合间隙小,结构精密,使用过程中不易漏风不易漏料(密封锁气),防堵耐用。密封优越,用感无忧:结构稳定,密封性能良好。可用于粉料、小颗粒物料,在正负极压差吸送过程中将物料分离排出。【电话/微信咨询:陈经理18068546632】适用于锂电正极材料输送,高镍三元材料,磷酸铁锂。阀体、端盖外表面采用不锈钢304.物料接触8-10mm尼龙工艺等。都可以满足工况耐磨,耐温尤为突出。 《扫二维码-添加 陈经理 微信-咨询产品》Rotary valve (commonly known as rotary feeder or star unloader, star discharge valve, ash discharge valve, star discharge valve, air lock valve, air shut-off fan, air shut-off fan unloader, air shut-off device, electric air lock device) is a specialized equipment used in powder (foam, granular material, powder particle mixture) conveying systems for unloading, metering, dust removal, quantitative conveying, mixing, and packaging. Rotary valves are widely used in industries such as lithium batteries, chemicals, environmental protection, petroleum, metallurgy, mining, refractory materials, electricity, steel mills, cement, plastics, grain and medicine.Tetrafluoroethylene is a chemically stable polymer material with excellent resistance to high and low temperatures and non adhesiveness, which can be used in extreme chemical environments. PTFE lining is a covering layer made on the surface of metals, ceramics, and other materials, mainly used for corrosion prevention, anti adhesion, and reducing friction.The PTFE lined rotary valve discharge valve is a specially designed valve made of PTFE material, which has excellent corrosion resistance and high temperature resistance.The impeller nylon rotary valve is suitable for unloading non touchable metal materials. Using whole piece nylon milling processing, the structure is reliable and operates without noise. Compared with ceramic valves, it can save costs and is the new favorite of the lithium battery industry.The nylon impeller has a small clearance with the shell, a precise structure, and is not prone to air or material leakage during use (sealed and locked), making it durable and anti blocking.查看详情 +

-

陶瓷卸料阀/ 陶瓷卸料阀,陶瓷星型卸料器,陶瓷旋转给料器

产品介绍本产品由本公司自主研制,已取得多项国家专 利。本品适用于不可接触金属物料,多用于锂电正极原料的生产制作。陶瓷阀的优点是超强耐磨,而且不会对锂电材料造成污染,是新能源大开发进程中一大助力。 主要结构:外壳金属。 物料接触部分:内衬陶瓷(也可尼龙、四氟等)。 适用范围:用于输送电池正极材料、磷酸铁锂、三元材料等。食品药材原料输送。 陶瓷卸料阀特点:1.耐腐蚀:能够抵御锂电材料中的腐蚀性介质。2.耐磨:硬度较高,能够承受物料的磨损。3.耐高温:适应锂电生产过程中的高温环境,不易变形或损坏。4.密封性好:确保物料在输送过程中不会泄露,保证生产环境的清洁和安全。5.保证物料的干净度。6.易于清洁:陶瓷表面光滑,不易粘附物料,方便清洗和维护。7.精准控制:能够实现对卸料量的精准控制,满足生产工艺要求。在锂电行业中陶瓷旋转阀卸料阀广泛应用于正极材料,负极材料,电解液等物料的输送和卸料,可以提高生产效率,保证物料的质量的和稳定性,同时满足环保和安全的要求。This product is independently developed by our company and has obtained multiple national patents. This product is suitable for non-contact metal materials and is mainly used in the production and production of lithium battery cathode materials. The advantage of ceramic valves is that they are super wear-resistant and do not cause pollution to lithium-ion materials, making them a major contributor to the development of new energy.Main structure: Metal shell.Material contact part: lined with ceramic (nylon, PTFE, etc.).Scope of application: Used for transporting battery cathode materials, lithium iron phosphate, ternary materials, etc. Transportation of food and medicinal materials.Characteristics of ceramic discharge valve: 1. Corrosion resistance: able to resist corrosive media in lithium battery materials. 2. Wear resistance: With high hardness, it can withstand the wear of materials. 3. High temperature resistance: Suitable for high temperature environments during lithium battery production, not easily deformed or damaged. 4. Good sealing: Ensure that materials do not leak during transportation, ensuring the cleanliness and safety of the production environment. 5. Ensure the cleanliness of materials. 6. Easy to clean: The ceramic surface is smooth and not easily adhered to materials, making it easy to clean and maintain. 7. Precision control: It can achieve precise control of the unloading amount and meet the requirements of the production process. Ceramic rotary valve discharge valves are widely used in the lithium battery industry for the transportation and discharge of positive electrode materials, negative electrode materials, electrolytes, and other materials. They can improve production efficiency, ensure the quality and stability of materials, and meet environmental and safety requirements.查看详情 +